The electric vehicle (EV) marketplace is expected to grow rapidly this decade. This latest Avery Dennison Performance Tapes white paper explores the use of films integrated with pressure-sensitive adhesive tapes in EV battery packs. The white paper sets the demand expectations with key research forecasts, including:

- Avicenne Energy forecasts the EV marketplace to grow from 2.3 million global sales in 2020 to 25.5 million sales by 2030, a CAGR of 27%

- Hybrids and plug-in hybrids are expected to account for another 21 million vehicles sold. This growth is driven by changing consumer tastes, regulation and legislative action such as the U.S. Inflation Reduction Act

- By 2030, EVs, HEVs, and PHEVs will require 2 million MWh of battery power. Global battery production will grow to 2,800 GWH.

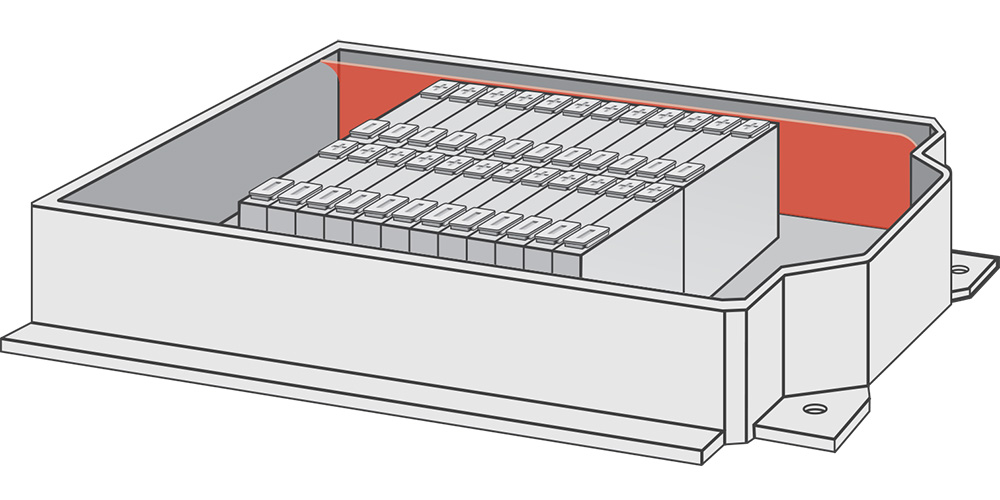

These insights bode well for manufacturers of battery packs used in EVs and other eMobility applications. Yet, significant engineering challenges remain, including the need for high-performance dielectric protection solutions that are cost-effective and highly compatible with modern, compact battery pack designs.

Due to this marketplace growth, there’s an increasing demand for EV battery packs that are reliable, safe and efficient. One of the critical design challenges facing manufacturers during this time is the prevention of electrical arcing. Traditional electrical insulation solutions often force EV battery manufacturers to make trade-offs involving cost, performance and mechanical properties. This white paper demonstrates how high-performance tapes offer not only the electrical insulation batteries need but can provide additional properties that make them a superior choice to traditional electrical insulation materials.

buy cheap lasuna – diarex online order himcolin buy online

order besifloxacin sale – besivance tubes buy sildamax sale

buy gabapentin tablets – buy neurontin 800mg generic azulfidine generic

purchase probalan pills – monograph online order carbamazepine 200mg online cheap

order mebeverine 135mg without prescription – buy etoricoxib online cheap pletal 100mg over the counter

order celecoxib 200mg pills – brand indomethacin order indocin 50mg pills

diclofenac 50mg price – aspirin 75 mg brand aspirin 75 mg pills

rumalaya tablets – shallaki order online buy amitriptyline 10mg online

mestinon 60mg cost – generic mestinon 60mg imuran price

voveran tablet – oral isosorbide purchase nimotop pills

ozobax drug – ozobax tablet feldene oral

purchase mobic generic – cost mobic ketorolac us

cyproheptadine buy online – purchase tizanidine online buy tizanidine medication

buy generic trihexyphenidyl – purchase artane online cheap purchase diclofenac gel online

where can i buy cefdinir – buy cleocin medication clindamycin generic

buy absorica online cheap – buy isotretinoin 40mg pill cost deltasone 10mg

buy permethrin for sale – oral tretinoin gel retin cream for sale

buy cheap generic betamethasone – purchase benoquin purchase monobenzone without prescription

flagyl 200mg pills – cheap metronidazole 400mg buy cenforce 100mg for sale

order generic augmentin – amoxiclav brand cheap synthroid tablets

buy clindamycin without a prescription – cleocin 300mg cheap buy indocin 75mg online cheap

hyzaar sale – order cephalexin 125mg online cheap keflex 500mg canada

purchase eurax cream – cheap eurax buy aczone without a prescription

buy zyban 150mg without prescription – buy ayurslim tablets brand shuddha guggulu

buy modafinil online cheap – cheap modafinil 100mg buy generic meloset over the counter

buy prometrium online cheap – buy ponstel generic fertomid brand

buy xeloda without a prescription – danazol 100 mg without prescription danazol canada

generic aygestin 5mg – order lumigan online cheap purchase yasmin generic

alendronate 70mg generic – nolvadex for sale online brand provera

purchase estrace pills – order ginette 35 arimidex ca

г‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ« гЃ®иіје…Ґ – г‚їгѓЂгѓ©гѓ•г‚Јгѓ« гЃЇйЂљиІ©гЃ§гЃ®иіј г‚їгѓЂгѓ©гѓ•г‚Јгѓ«гЃ®йЈІгЃїж–№гЃЁеЉ№жћњ