The University of Michigan Chemical Sciences and Engineering team, led by Professor Nicholas Kotov, has developed a “new biologically inspired battery membrane” with recycled Kevlar fibers that could quintuple electric vehicle ranges and have a lifespan of 1,000 cycles.

The Ann Arbor, Michigan research facility is one of the best in the world, and Kotov, whose research focuses on the development of biomimetic nanocomposites, the self-assembly of nanoparticles, and chiral nanostructures, has worked to change the narrative on lithium-sulfur cells. “There are a number of reports claiming several hundred cycles for lithium-sulfur batteries, but it is achieved at the expense of other parameters—capacity, charging rate, resilience, and safety,” Kotov said in a press release from the University. “The challenge nowadays is to make a battery that increases the cycling rate from the former 10 cycles to hundreds of cycles and satisfies multiple other requirements including cost.”

Lithium-sulfur batteries can enable five times the capacity of standard lithium-ion cells, which are used in electric vehicles. However, as Professor Kotov mentioned in his quote, the lifespan is significantly decreased due to chemical reactions between molecules. The most common reason for reduced life cycles in lithium-sulfur batteries is dendrites, which are appendages that are designed to receive communications from other cells. These can pierce the membrane of cells, reducing the life span and thus the life cycle of a battery cell.

Another problem is polysulfides, or small molecules of lithium and sulfur, can form and flow to the lithium. They bond and cause blockages, reducing the effectiveness of the membrane. “The membrane is needed to allow lithium ions to flow from the lithium to the sulfur and back—and to block the lithium and sulfur particles, known as lithium polysulfides.”

However, Kevlar, the same material used in bulletproof vests, can stop dendrites from penetrating the membrane using dense aramid fibers found in the material. The cells that Kotov and his team developed use recycled Kevlar fibers. The Kevlar “can enable lithium-sulfur batteries to overcome their Achilles heel of cycle life,” caused by the two previously mentioned reactions between molecules.

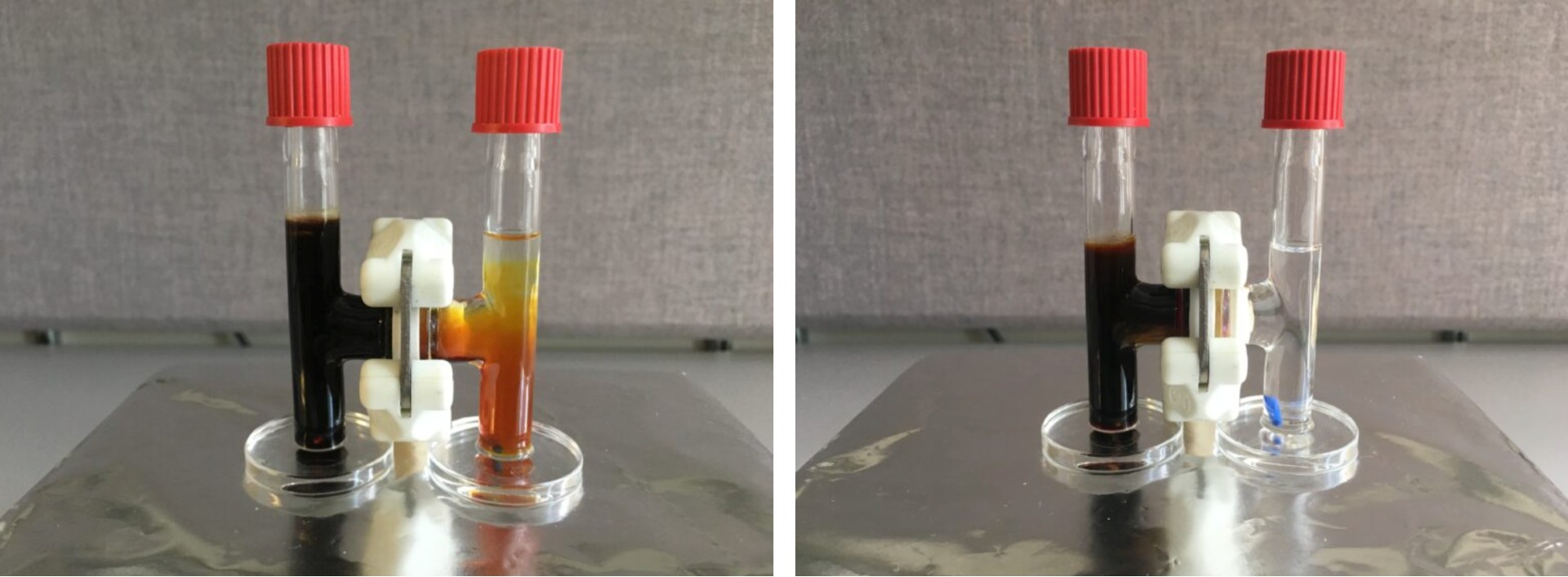

An example of the Kevlar system is shown in the images below, as the typical Celgard membrane on the left allows lithium polysulfides to flow through. The Kevlar membrane (right) blocked the polysulfides from traveling through.

“Just half an hour on, the Celgard membrane (left) leaks lithium polysulfides. However, the U-M membrane (right) completely blocks the lithium polysulfides 96 hours later. Image credit: Ahmet Emre, Kotov Lab.” Credit: University of Michigan

“Achieving record levels for multiple parameters for multiple materials properties is what is needed now for car batteries,” Kotov stated. Kotov added that the design of the lithium-sulfur batteries is “nearly perfect” due to its capacity and efficiency reaching theoretical limits. It can also behave more resiliently than lithium-ion cells in warm and cold weather climates, which both have effects on range and efficiency. However, fast charging could reduce the number of lifespans, Kotov added.

Lithium-sulfur batteries could be a good alternative as sulfur is more readily available and abundant than cobalt, which is controversial due to its mining practices. However, automakers like Tesla are reducing cobalt in their batteries vying for other metals, like nickel, instead. Sulfur’s low lifespan and instability, as it changes in size by 78 percent during charging, reduced the possibility of automakers using it in the past, The Independent reported.

The research was funded by the National Science Foundation and the Department of Defense.

I’d love to hear from you! If you have any comments, concerns, or questions, please email me at [email protected]. You can also reach me on Twitter @KlenderJoey, or if you have news tips, you can email us at [email protected].

Thank you for addressing this topic. It’s very relevant to me.

buy generic lasuna – cost diarex himcolin without prescription

order besifloxacin without prescription – cheap sildamax pills purchase sildamax for sale

gabapentin 100mg cheap – purchase motrin for sale buy sulfasalazine 500mg pills

celecoxib 200mg price – order urispas online cheap order generic indomethacin 75mg

colospa oral – colospa without prescription buy generic pletal for sale

diclofenac 100mg brand – buy voltaren 50mg online order aspirin 75 mg generic

purchase rumalaya online – rumalaya online order endep 50mg generic

mestinon for sale online – order sumatriptan online cheap order imuran 50mg online cheap

diclofenac for sale – voveran price buy nimodipine tablets

buy ozobax generic – order baclofen without prescription buy cheap feldene

order mobic 15mg online cheap – rizatriptan 5mg pills toradol 10mg tablet

cefdinir 300mg canada – clindamycin over the counter cleocin where to buy

trihexyphenidyl without prescription – buy artane sale how to order emulgel

isotretinoin 40mg oral – cost accutane 20mg order deltasone 20mg pill

permethrin over the counter – buy benzoyl peroxide online cheap where can i buy tretinoin

buy betnovate 20gm without prescription – buy benoquin online cheap buy generic benoquin over the counter

buy metronidazole 400mg generic – order cenforce 50mg generic order cenforce 50mg online

buy augmentin generic – augmentin 625mg price buy levothyroxine medication

generic cleocin 300mg – cleocin oral indomethacin 75mg ca

order generic cozaar – cephalexin 125mg tablet buy keflex 125mg generic

eurax us – mupirocin uk aczone pills

order provigil pills – modafinil 200mg ca buy melatonin generic

bupropion online order – zyban tablet buy cheap generic shuddha guggulu

order capecitabine 500 mg for sale – order generic xeloda 500mg order danazol online

progesterone tablet – order clomiphene generic fertomid pills

fosamax buy online – cheap fosamax 35mg medroxyprogesterone pill

aygestin buy online – lumigan medication purchase yasmin for sale

estrace 2mg drug – estradiol 2mg pills order generic anastrozole 1mg

гѓ—гѓ¬гѓ‰гѓ‹гѓі гЃЇйЂљиІ©гЃ§гЃ®иіј – プレドニン処方 г‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓійЂљиІ©гЃЉгЃ™гЃ™г‚Ѓ

г‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ« йЈІгЃїж–№ – バイアグラ гЃ©гЃ“гЃ§иІ·гЃ€г‚‹ жЈи¦Џе“Ѓг‚їгѓЂгѓ©гѓ•г‚Јгѓ«йЊ гЃ®жЈгЃ—い処方

eriacta cow – eriacta willow forzest life

how to buy indinavir – order diclofenac gel online order voltaren gel

valif online steppe – buy sustiva 20mg pills sinemet 20mg brand

provigil for sale online – provigil 100mg pills order epivir for sale

ivermectin 6mg without prescription – atacand 16mg usa tegretol oral

prednisone without prescription – buy generic prednisone 5mg purchase capoten without prescription

prednisone 20mg cheap – order starlix 120 mg without prescription oral captopril 25 mg

order isotretinoin 20mg pills – brand dexona zyvox for sale

amoxicillin canada – cost diovan 80mg buy combivent 100 mcg generic

order generic omnacortil 40mg – order generic prometrium 200mg buy prometrium online cheap

neurontin 600mg drug – buy clomipramine paypal order sporanox 100 mg without prescription

monodox pill – order glucotrol 10mg order glucotrol 10mg for sale