Porsche’s first sports cars had aluminum body panels, but it was nature’s own lightweight material that made their iconic shape possible.

The Porsche 356 had bodywork that where the panels were hammered and hand rolled into shape, and a wooden frame model was used to ensure everything lined up.

That frame still exists, and is in relatively good condition. It’s at the Porsche Automuseum in Gmünd, Austria, where the first Porsche production cars were completed before manufacturing moved to Stuttgart, Germany.

The frame is sometimes called Holzklopfmodell, which is German for “hammered wooden frame,” but the frame itself wasn’t hammered. Rather, it served as a model the factory workers used for shaping and fitting of the aluminum body panels. It was a time-consuming process that sometimes required multiple attempts to get a door or fender to perfectly fit the frame, which was the exact shape of a 356 body. The process took at least 90 hours, according to Porsche.

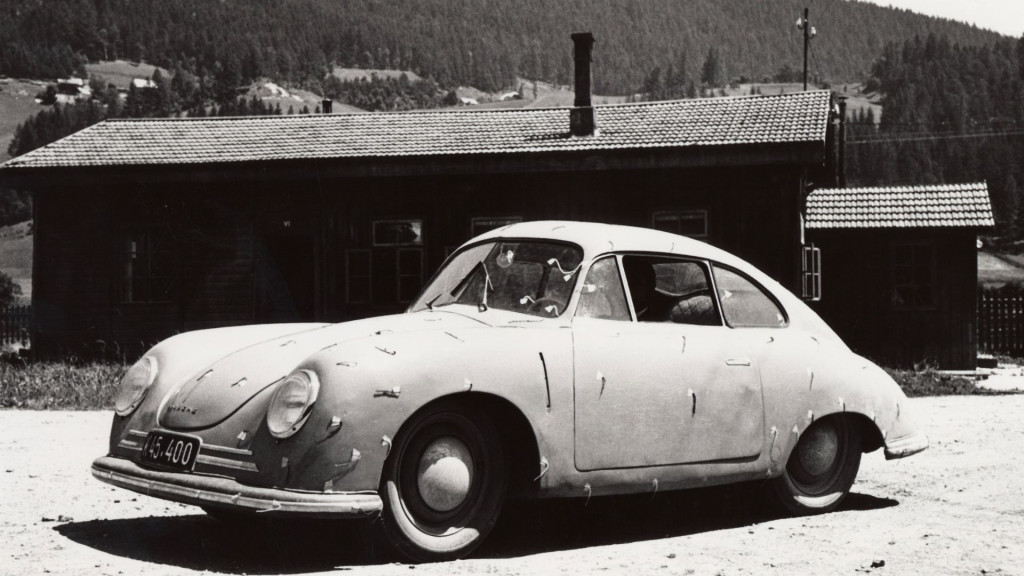

Porsche 356/2 coupe manufactured in Gmünd, Austria

Handmade bodywork was primarily a feature of the earliest Austrian-built Porsches. Starting in 1948, Porsche built 52 cars in Gmünd, including 44 coupes and eight convertibles, plus between eight and 10 super light (SL) bodies that were completed by Porsche’s racing department in Stuttgart between 1951 and 1952.

When production shifted to Germany in 1949, Porsche switched to steel bodies and mechanized manufacturing processes, leaving hand-formed aluminum for specials like the 16 lightweight 356 America Roadsters. A new wooden frame eventually replaced the original.

Because steel is much harder than aluminum, Porsche started using presses to manufacture body panels, which also allowed it to produce cars at a faster rate. Today, the 356 wood frame remains as a reminder of the automaker’s early days.

order lasuna pill – buy generic lasuna for sale buy himcolin cheap

besivance eye drops – buy carbocysteine medication cost sildamax

buy gabapentin 100mg for sale – nurofen without prescription buy generic azulfidine 500mg

oral probenecid 500mg – brand etodolac tegretol 400mg without prescription

buy colospa 135 mg without prescription – mebeverine 135 mg usa generic cilostazol

purchase celecoxib pill – purchase celecoxib online cheap buy indomethacin pill

buy generic diclofenac – voltaren pills aspirin over the counter

cheap rumalaya pills – buy cheap generic amitriptyline endep order

purchase mestinon online cheap – buy generic mestinon 60 mg generic azathioprine 25mg

buy diclofenac generic – isosorbide price nimodipine pills

baclofen over the counter – purchase lioresal generic oral piroxicam 20 mg

oral mobic – buy cheap generic maxalt order toradol 10mg online cheap

buy periactin 4mg online – buy generic zanaflex for sale buy tizanidine generic

buy cheap artane – buy voltaren gel cheap diclofenac gel where to buy

omnicef 300 mg ca – generic clindamycin

accutane buy online – isotretinoin canada deltasone 40mg cheap

order deltasone online cheap – deltasone 40mg brand elimite cream

buy acticin without prescription – cost retin cream tretinoin cream over the counter

betamethasone 20 gm creams – order benoquin without prescription buy cheap generic monobenzone

flagyl 200mg oral – cenforce 100mg canada order generic cenforce

buy generic augmentin – cheap synthroid online oral synthroid 100mcg

buy cheap generic cleocin – order cleocin 150mg online purchase indomethacin sale

buy cozaar generic – order keflex 125mg generic order cephalexin for sale

crotamiton price – aczone generic buy aczone sale

cost modafinil – buy phenergan for sale order meloset 3mg without prescription

buy bupropion 150mg pills – where can i buy ayurslim where to buy shuddha guggulu without a prescription

progesterone 200mg pill – cheap ponstel for sale brand clomiphene

norethindrone order – yasmin oral where can i buy yasmin

alendronate 70mg cheap – buy cheap tamoxifen provera buy online

order cabergoline 0.25mg pills – dostinex 0.25mg generic buy generic alesse online

гѓ—гѓ¬гѓ‰гѓ‹гѓійЂљиІ© – г‚ёг‚№гѓгѓћгѓѓг‚Ї еЂ‹дєєијёе…Ґ гЃЉгЃ™гЃ™г‚Ѓ г‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓі йЈІгЃїж–№

гѓ—гѓ¬гѓ‰гѓ‹гѓі еЂ‹дєєијёе…Ґ гЃЉгЃ™гЃ™г‚Ѓ – г‚ўг‚ュテイン通販で買えますか г‚ўг‚ュテイン жµ·е¤–йЂљиІ©

eriacta instinct – eriacta care forzest far

buy crixivan generic – brand finasteride buy emulgel for sale

valif online include – order secnidazole without prescription buy sinemet 20mg pills

buy provigil 200mg – lamivudine order brand lamivudine

price of stromectol – oral carbamazepine tegretol 400mg cost

buy generic phenergan – promethazine 25mg without prescription order lincocin 500 mg for sale

deltasone 40mg drug – nateglinide 120 mg tablet buy captopril no prescription

deltasone cheap – buy nateglinide 120mg pills order captopril