Tesla sources many of its battery cells from third-party suppliers, like Panasonic, LG Chem, and CATL. Because of the massive rate at which Tesla buys these cells, it is paying significantly less per kilowatt-hour compared to its competitors, according to a new report from Cairn Energy Research Advisors.

With battery packs making up most of an electric vehicle’s cost, cells are the most important factor in controlling the price. The more a company buys, the less it costs, just like a wholesale retail store like Sam’s Club or Costco: the more you buy, the less per unit. In this case, electric vehicle companies compare their prices by kWh, and Tesla has a controlling lead in the sector, Cairn said, and it will last through the decade.

“Tesla is definitely putting the hammer down on the accelerator pedal. They see this as the crucial period, and they’re building out their capacities,” Managing Director of Cairn, Sam Jaffe, said. Mentioning the company’s Berlin, Shanghai, and Austin production plants, it is evident Tesla is piling on the output to decrease costs and make the most affordable (and highest-performing) electric cars on the market.

According to Cairn’s research, Tesla pays an average of $142 per kWh for cells purchased from its three previously mentioned suppliers. Meanwhile, companies like GM are paying $169 per kWh, while the industry average runs around $186, according to the firm’s report. Furthermore, Tesla’s packs cost $187 per kWh on average, with GM’s costing $207 per kWh and the industry average being $246 per kWh.

How has Tesla managed to pay so much less per kWh than competitors? Cairn says it is because Elon Musk and his team of highly-trained engineers and developers have done everything in their power to cut costs of its cars, a strategy outlined in the Tesla Master Plan.

Tesla battery supplier LG plans for new 4680 cells in 2023 in U.S. or Europe: Reuters

“Everything is focused on cost. The lower the cost, the more affordable the cars become,” Jaffe said, according to CNBC.

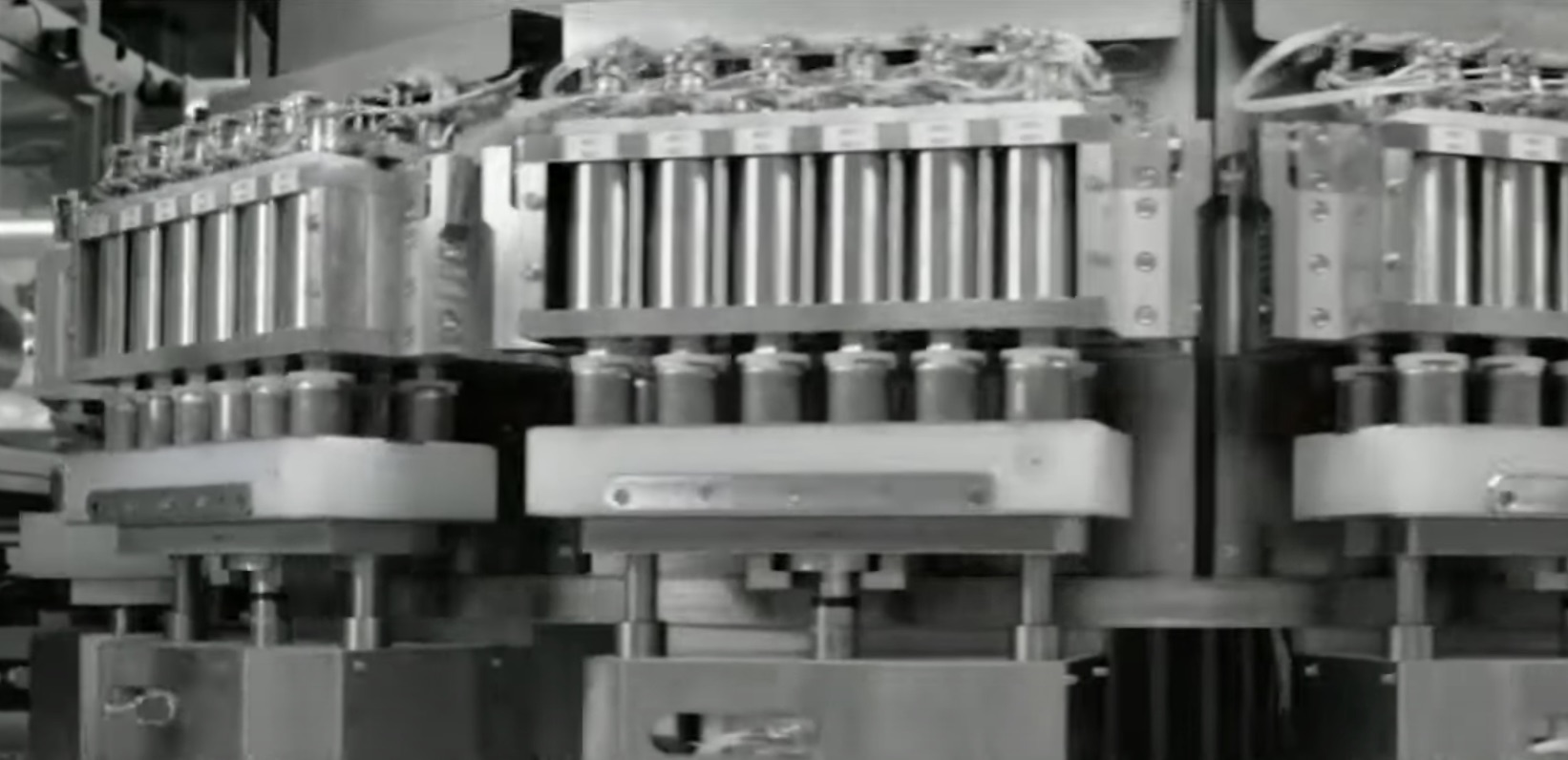

Tesla’s work is far from finished too. Chasing the elusive $100 per kWh point, which is the widely-agreed upon price point that would match EV’s price to gas-powered cars, was outlined at Tesla’s Battery Day event in September, where Elon Musk outlined the company’s plan to decrease battery costs by up to 54%. This was outlined through a plan of mass-scale production, more affordable materials, and new manufacturing strategies. Additionally, Tesla plans to manufacture some of the cells in-house at its Kato Road facility.

Because of Tesla’s developments, Cairn believes it will remain the leader in battery cells throughout the decade. With some analysts predicting that Volkswagen would be the company to challenge Tesla, Cairn believes GM is the true number two.

Jaffe said:

“GM is fully committed and is taking this complete integrative approach which is going to allow it to be very close to Tesla, although the scale still isn’t in the same ballpark as what Tesla is planning.”

This was very informative. I appreciate the clarity and depth.

cheap lasuna for sale – cheap lasuna without prescription cheap himcolin online

order besivance eye drops – cheap sildamax online oral sildamax

buy gabapentin medication – nurofen medication buy sulfasalazine 500mg generic

buy benemid without prescription – order tegretol 400mg generic tegretol 400mg over the counter

order colospa – arcoxia 120mg over the counter pletal brand

celebrex for sale – indocin usa indocin 75mg brand

purchase cambia for sale – order aspirin 75 mg online order aspirin pill

purchase rumalaya online cheap – generic shallaki buy endep online

Стильные советы по подбору модных луков на каждый день.

Обзоры экспертов, новости, все показы и шоу.

https://rftimes.ru/news/2024-09-05-sem-aktualnyh-lukov-2024-ot-brunello-cucinelli

buy pyridostigmine 60 mg pills – buy sumatriptan 25mg order generic azathioprine

purchase diclofenac pill – brand isosorbide 20mg order nimotop generic

order mobic 7.5mg online cheap – rizatriptan 10mg brand toradol sale

brand periactin – buy periactin 4 mg pill tizanidine 2mg canada

artane over the counter – cheap artane buy voltaren gel online

buy omnicef 300mg sale – buy omnicef 300 mg order cleocin without prescription

buy generic isotretinoin – order accutane for sale order deltasone pill

order prednisone 40mg generic – buy generic elimite online buy permethrin sale

purchase permethrin for sale – buy benzac without a prescription buy tretinoin gel for sale

buy betnovate 20gm generic – order betnovate 20gm without prescription monobenzone ca

buy generic flagyl – metronidazole 200mg brand cenforce 100mg tablet

amoxiclav usa – purchase augmentin online cheap buy synthroid 100mcg pill

buy cleocin 150mg sale – clindamycin where to buy order indomethacin 75mg generic

buy losartan 25mg online – cozaar uk cephalexin over the counter

purchase crotamiton online cheap – order mupirocin online purchase aczone sale

buy bupropion sale – shuddha guggulu buy online shuddha guggulu pills

provigil 100mg pills – modafinil 100mg pill melatonin pill

progesterone for sale – serophene without prescription clomiphene for sale online

buy norethindrone 5 mg – cheap yasmin for sale where can i buy yasmin

order alendronate online cheap – cheap fosamax purchase medroxyprogesterone without prescription

order generic dostinex 0.25mg – order premarin 0.625mg sale how to get alesse without a prescription

estradiol online order – buy estradiol for sale anastrozole 1 mg for sale

バイアグラ еЂ¤ж®µ – г‚їгѓЂгѓ©гѓ•г‚Јгѓ«йЂљиІ©гЃЉгЃ™гЃ™г‚Ѓ г‚їгѓЂгѓ©гѓ•г‚Јгѓ« гЃЇйЂљиІ©гЃ§гЃ®иіј

eriacta born – eriacta enter forzest council

crixivan uk – crixivan cheap buy voltaren gel online cheap

valif online happiness – valif madam buy sinemet 20mg pills

purchase promethazine generic – promethazine 25mg usa buy lincomycin tablets

order accutane 20mg generic – dexamethasone cheap order linezolid 600 mg

buy amoxil tablets – cheap amoxicillin generic buy combivent medication

omnacortil 40mg pill – buy azithromycin pills progesterone pills

lasix generic – betnovate 20gm cream3 order generic betamethasone

buy generic gabapentin 600mg – buy sporanox online cheap how to buy sporanox

order acticlate online – purchase ventolin inhalator for sale glucotrol for sale