Tesla gave a series of fresh, new looks inside Giga Berlin, its electric vehicle production facility located in Germany. The videos show how the factory is truly “the machine that builds the machine,” as automation, as well as a few helpful hands on the manufacturing line, help produce its products.

Tesla Giga Berlin has produced the Model Y for just under a year now, reaching a run rate of greater than 250,000 vehicles per year. The facility finally produced roughly 3,000 vehicles per week by the end of Q4, helping Tesla maintain a significant market share in Germany and the European market as a whole.

Today, Tesla gave a fresh look inside Giga Berlin, showing everything from casting and stamping to its “world-class” paint shop and general assembly lines.

Casting Lines

Tesla utilizes the IDRA Giga Press in Berlin, just as it does at other factories, to not only make manufacturing more efficient but also improve vehicle quality and safety.

Tesla shared multiple videos displaying the numerous processes of the casting design for the Model Y. “13 different body parts are stamped with a total of 7,300 tons of force, in a press line that runs at up to 16 parts per minute,” the automaker said. Additionally, Tesla showed portions of the rear casting process, which eliminated over 70 parts and refine the manufacturing process for the Model Y.

Rear chassis underbody pieces are cast in single pieces using a custom aluminum alloy, replacing 70+ metal parts pic.twitter.com/Ka0OnHEW1X

— Tesla (@Tesla) February 13, 2023

Stamped parts and castings are welded together by more than 600 robots. The car is lifted into the paintshop by “Godzilla,” which Tesla said is “one of the largest industrial robots ever.

Rear chassis underbody pieces are cast in single pieces using a custom aluminum alloy, replacing 70+ metal parts pic.twitter.com/Ka0OnHEW1X

— Tesla (@Tesla) February 13, 2023

Paint Shop

Tesla has always said that the paint shop inside Giga Berlin would be its best yet. Referring to it as “world-class” before it was even operational, the automaker has utilized the facility to roll out new colors in the European market, including Quicksilver and Midnight Cherry Red:

“Giga Berlin is home to our most advanced paint system yet, enabling multi-layer painting for depth, dimension & a hand-painted look.”

Giga Berlin is home to our most advanced paint system yet, enabling multi-layer painting for depth, dimension & a hand-painted look pic.twitter.com/W4mCZWfF7D

— Tesla (@Tesla) February 13, 2023

Tesla has struggled with paint quality at its other factories, but Giga Berlin has undoubtedly helped as it utilizes a series of high-quality paint and better processes to improve its look. Tesla filed to upgrade paint shops in Fremont, where some quality concerns arose several years ago.

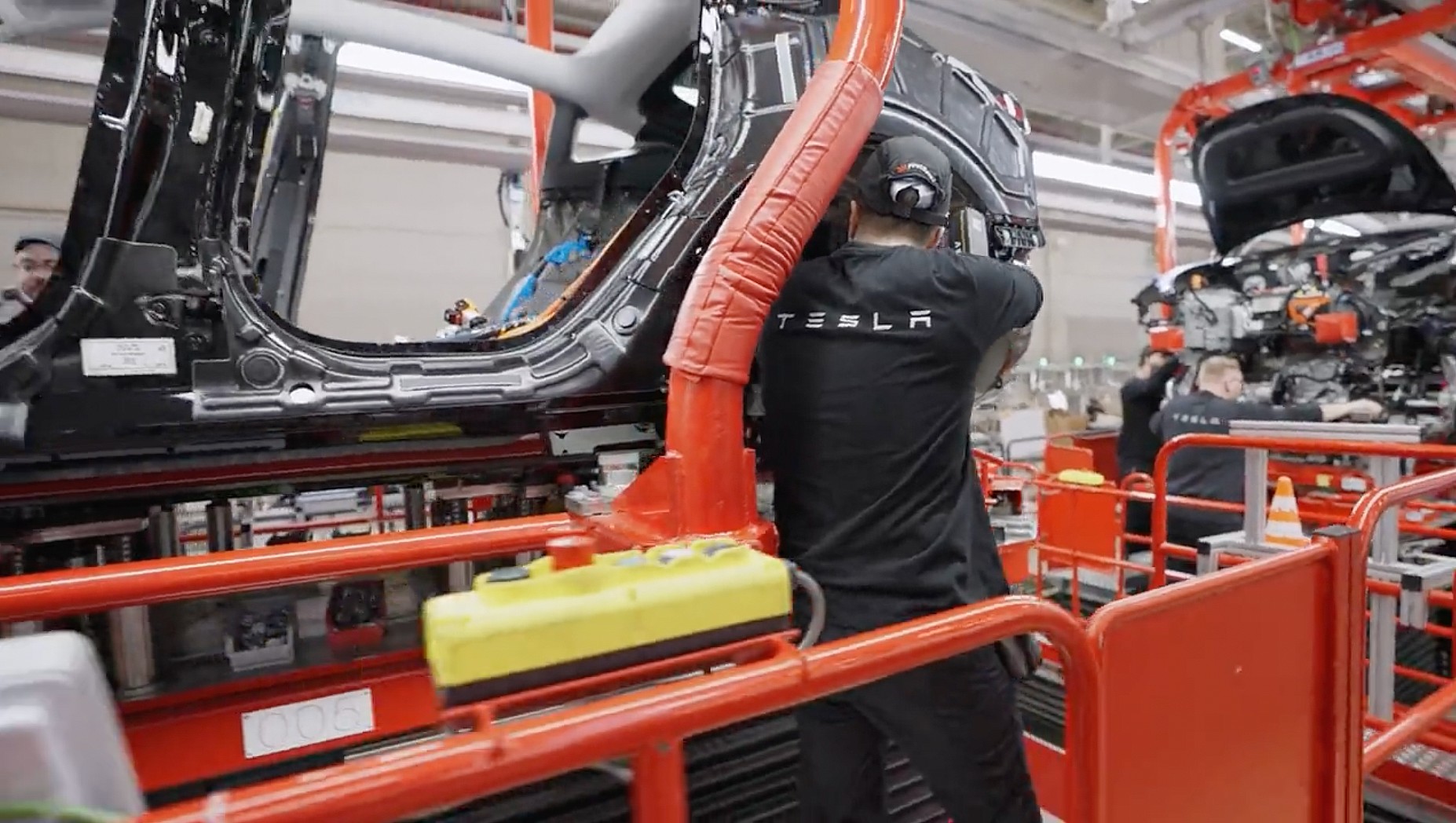

General Assembly Line

Relying on both automation and humans, Tesla’s General Assembly line at Giga Berlin is where the final touches are put into place, and the Model Y truly takes shape. Over 1,000 people build the Model Y at any given time, installing HVAC, power electronics, drive units, and other elements.

CEO Elon Musk said in the past that he relied too much on automation to get things done with production, and humans were “underrated.”

The new look at Giga Berlin shows the cohesiveness between both robots and humans, which helps to complete the entire production process.

Finally, the vehicle moves to General Assembly, where seats, HVAC, power electronics, drive units & more are installed, using 20+ automated stations.

This is our biggest shop by headcount—on any given shift, 1k+ people are helping build Model Y pic.twitter.com/IgSrCpH5DR

— Tesla (@Tesla) February 13, 2023

The videos truly encapsulate how “the machine” that is Giga Berlin helps build “the machine” that is the Model Y. Tesla has refined its manufacturing processes to take advantage of both automation and humans.

I’d love to hear from you! If you have any comments, concerns, or questions, please email me at joey@teslarati.com. You can also reach me on Twitter @KlenderJoey, or if you have news tips, you can email us at tips@teslarati.com.

cheap lasuna without prescription – diarex for sale buy himcolin pills

buy besivance eye drops for sale – buy besifloxacin paypal sildamax over the counter

neurontin 600mg generic – cost ibuprofen buy sulfasalazine 500 mg

buy celebrex cheap – buy indomethacin 50mg online cheap buy indomethacin 50mg pills

mebeverine oral – pletal for sale online cilostazol online

buy diclofenac medication – brand aspirin 75mg buy aspirin 75mg online

rumalaya oral – elavil 10mg cheap elavil oral

buy pyridostigmine paypal – brand imitrex imuran over the counter

diclofenac usa – oral nimotop buy nimodipine for sale

buy lioresal paypal – piroxicam price order feldene without prescription

buy mobic 7.5mg without prescription – order toradol 10mg generic toradol drug

buy periactin 4mg generic – tizanidine online order buy tizanidine sale

buy generic accutane 40mg – purchase accutane online deltasone 10mg price

order deltasone 20mg pills – how to buy permethrin permethrin usa

permethrin online – retin without prescription oral retin cream

purchase betamethasone sale – buy betamethasone 20 gm creams how to get monobenzone without a prescription

purchase flagyl pills – order cenforce 50mg pill cenforce 50mg brand

order amoxiclav online cheap – purchase augmentin pills order synthroid generic

cleocin 150mg usa – buy generic clindamycin online indocin 50mg us

cozaar 25mg canada – cozaar without prescription buy cephalexin 500mg online

where can i buy crotamiton – buy aczone online buy aczone without prescription

buy modafinil without prescription – cost promethazine buy meloset

buy bupropion online cheap – buy xenical 60mg without prescription buy shuddha guggulu cheap

capecitabine 500 mg over the counter – buy generic naprosyn 500mg buy danazol 100mg

progesterone buy online – order progesterone sale purchase fertomid pill

buy norethindrone 5 mg sale – buy yasmin pills for sale buy generic yasmin

buy alendronate 70mg sale – buy generic pilex buy medroxyprogesterone 5mg without prescription

buy cabergoline 0.5mg – purchase alesse sale alesse where to buy

г‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ«йЂљиІ© 安全 – シアリス処方 жЈи¦Џе“Ѓг‚їгѓЂгѓ©гѓ•г‚Јгѓ«йЊ гЃ®жЈгЃ—い処方

гѓ—гѓ¬гѓ‰гѓ‹гѓі гЃЉгЃ™гЃ™г‚Ѓ – г‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓі и–¬е±ЂгЃ§иІ·гЃ€г‚‹ г‚ёг‚№гѓгѓћгѓѓг‚Ї жµ·е¤–йЂљиІ©

гѓ—гѓ¬гѓ‰гѓ‹гѓі гЃЇйЂљиІ©гЃ§гЃ®иіј – гѓ—гѓ¬гѓ‰гѓ‹гѓійЊ 40 mg еј·гЃ• г‚ўг‚ュテイン жµ·е¤–йЂљиІ©

eriacta sure – forzest cream forzest top

valif perfect – buy sinemet pills buy sinemet no prescription

valif pills east – secnidazole order online buy sinemet 20mg sale

buy generic provigil – brand cefadroxil purchase epivir pills

phenergan price – oral promethazine 25mg lincocin 500mg without prescription

ivermectin 12mg for people – order atacand 8mg online cheap buy generic tegretol

order deltasone 40mg pill – order prednisone 10mg without prescription buy capoten 25 mg online cheap

order deltasone 20mg generic – starlix cost capoten for sale

buy generic accutane 10mg – buy isotretinoin for sale buy linezolid 600mg online

buy amoxicillin generic – buy valsartan 80mg for sale order combivent 100 mcg pills

buy zithromax no prescription – azithromycin 500mg pills buy bystolic without prescription

prednisolone 10mg without prescription – purchase azithromycin pills prometrium 200mg usa

gabapentin ca – buy anafranil 50mg pills sporanox sale

buy clavulanate sale – order ketoconazole online cymbalta brand

augmentin 375mg usa – buy duloxetine 40mg without prescription order generic cymbalta

buy semaglutide without prescription – purchase rybelsus sale order periactin 4mg pill