Tech: John Deere: High Tech Down on the Farm

Higher Farm Yields through Innovation, Advanced Technology and Sustainability

The sight of a farmer sitting in a tractor for hours and hours working a field is being replaced by a semi-automated agricultural machine with no human behind the wheel. Similar to what is happening in the automotive world, farm machines will become more reliant on state-of-the-art technology with automation, satellite navigation, data collection, and making the move to electrification or renewable fuels.

Farmers learn early on that practicing sustainable agriculture will produce higher yields. The methods include knowing when to till the soil, plant, fertilize, spray for insects, and harvest in a way that protects the environment and makes the best use of renewable resources. It is daunting to think all of these are dependent on the weather and the availability of labor in order to have a successful crop, which is vital to feeding the country. While nothing can be done about the weather, something is being done about labor.

One of the leaders in farm machine technology is John Deere & Company, based in Moline, Illinois. John Deere, a blacksmith, revolutionized farming with the invention of the self-scouring steel plow in 1837. Now, the company’s green and yellow machines’ ubiquity throughout America and the world is a clue to the innovation that is brought to the market, foreseeing the needs of John Deere customers.

Sustainability through Alternative Propulsion/Fuels

Electrification is the next step for John Deere as it has set a goal of a 30-percent carbon reduction by 2030. Earlier this year saw the introduction of its first-ever all-electric machine, the Electric ZTrak residential driving mower. Moving-up in size, the next to be launched will be the electric-powered 310 X-Tier electric backhoe, 244 X-Tier compact wheel loader, and the 145 X-Tier excavator. The 310 X-Tier electric backhoe will launch before 2026 and will have a 120 kilowatt-hour (kWh) battery and a 12-hour run time.

For the heavier machines that will need more range and driving distance, John Deere is turning to hybrid engines and conventional engines that will use biofuel-based diesel or a gasoline/ethanol blend. John Deere has more than three million hours on vehicles powered by hybrid engines already reducing the C02, so there is no proof-of-concept needed, just a continued roll-out of these engines into all of their machines.

Biodiesel/renewable diesel and ethanol, produced from plant waste such as soy beans, corn and sugar cane, are currently being used in ground transportation and home heating. Airlines testing biofuels include British Airways, Emirates, Jet Blue, KLM, Lufthansa, United Airlines and Virgin Australia and Atlantic Airlines. The United States, as of 2022, was the world’s largest producer of biodiesel and ethanol, with Brazil and Indonesia the next largest producers.

According to John Deere, corn ethanol has a Greenhouse Gas Intensity 44% – 52% lower than gasoline, and soybean diesel 66% less than petroleum diesel. Note: Greenhouse Gases, (GHGs) are a group of substances that contribute to global warming, including carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), sulphur hexafluoride (SF6), perfluorocarbons (PFCs), hydrofluorocarbons (HFCs) and many other compounds. While GHGs are released from natural sources, the combustion of fossil fuels, agricultural activities, waste generation and industrial processes have increased their concentrations.

Automated and Semi-automated Farm Machinery

Adaptive or smart cruise control, first used in automobiles in the early 1990s, is the basis for the advanced driver-assistance systems (ADAS) that now includes lane keep assist, predictive and emergency braking and hands-free driving. It was around this same time John Deere, at their Technology and Innovation Center in Champagne, Illinois, began developing the use of artificial intelligence, automation and connectivity for integration into their machines. The parallel to what companies in the Silicon Valley in California were doing is apparent.

The John Deere programmable automated and semi-automated tractors integrate technology of cameras, sensors, artificial intelligence and ultra-fast processors that allow farmers to perform time-intensive repetitive tasks automatically. This includes tilling, planting, spraying and harvesting, all of which could take a crew of laborers weeks to accomplish. When utilizing automated and semi-automated tractors, these tasks are completed in a matter of days without the need for many conventional laborers.

How It Works

Full and semi-autonomy does not mean humans are no longer a part of farming. The technology frees-up the farmer to monitor a job as a supervisor who can be in an office or a pickup using a laptop or pad computer to program the machine, using app technology for tasks a human would do behind the wheel.

Before an automated tractor can begin doing any work it needs to know the boundaries of the job. This is accomplished by geo-fencing using a drone, or truck driving the perimeter of the field. The coordinates are uplinked and entered into John Deere proprietary software, then through Data Sync sent to the tractor. Once downloaded, the tractor can then set off to run day and night, depending on the task.

Tilling/Planting/Spraying

Tilling can be performed at different times of the year. Pre-planting is to break-up the soil and create rows for planting, while post-harvest is to turn any remaining plant material back into the soil where it can begin the decomposing process.

With only a short 10-day window to plant each crop due to changing weather conditions, this is where accuracy and programming steps-up a notch. John Deere has developed several machines that can, at any desired interval or depth, plant a seed and then immediately after it hits the soil get a squirt of fertilizer and then covered up. In the case of corn it would be dropping a seed every 6-inches apart and 2-inches deep. Imagine this going on for hours at a time with precision, which is critical for a high yield crop. All done through GPS mapping, the automated planting process is precise and efficient.

30-percent of the cost of growing consists of spraying jobs of fertilizing, weed and pest control. John Deere has invented a machine called a See & Spray. It uses 400 sensors, cameras and software programmed to recognize a weed versus a desired plant. In a fully automated process, cameras “see” the plants and “sprays” weed control or fertilizer.

Harvesting

When it is harvest time, just like planting, time is crucial as there may be a very short window to get the crop in. Harvesters or combines perform multiple tasks that previously had been all done by hand. Specially designed for corn, cotton, soybeans, sugar cane or wheat, the harvesters can be programmed to go through a field with high success. In the case of corn the ears are removed, run through a machine that removes the kernel, and then separates the plant material and off-loads the kernels and plant in following trucks. Programmers can also set the machine to separate cotton and soybeans from the plant, or sugar cane and wheat to be cut and thrashed with the chaff hauled away.

Mission Control

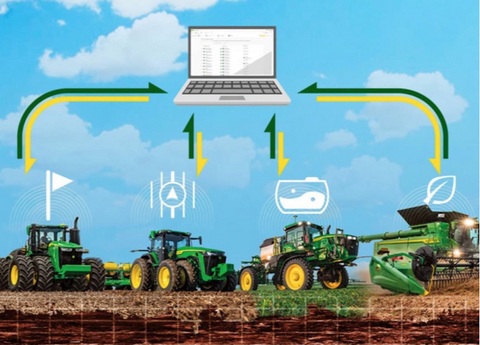

None of the in-field activities can take place without the John Deere Operations Center where data is collected, and then through cellular service sent to the automated tractor. This connectivity also includes in-field data sharing between machines as they learn from each other: the tiller sets the rows which the planter, sprayer and harvester work from.

The importance of cellular and satellite connectivity cannot be overstated as, without guidance data being uploaded and downloaded, nothing in the field will be accomplished. The United States has 85-percent cellular and satellite service coverage, which makes communicating with automated farm machines possible. Brazil, the company’s second largest market, only has a small fraction of that coverage, so John Deere is investing in a dedicated satellite just for agriculture in that country.

Farm Machinery Technology

If you have driven a late-model car, SUV or truck recently (like all the ones reviewed on Clean Fleet Report), you have experienced the same type of technology found in modern farm machinery. The major difference is that, on a farm, the boundaries and variables of an agricultural field are finite, whereas out on streets and highways, they are infinite. This makes the adoption of advanced driver-assistance systems more challenging for auto manufacturers, but does not take away anything from what John Deere engineers have and will be accomplishing.

The importance of increasing the widespread use of automated and semi-automated agriculture machines cannot be understated, especially when they are powered by clean or renewable fuels. Farms continue to be consolidated into larger and larger acreage where GPS-controlled machines will be needed to do repetitive work accurately, efficiently and with minimal supervision. Soon many of them may be self-driving electric machines.

Make sure to opt-in to the Clean Fleet Report newsletter (top right of page) to be notified of all new stories and vehicle reviews.

Story by John Faulkner. Photos by John Faulkner and John Deere.

They don’t want you to see this. https://groups.google.com/g/tt6y6rr4/c/H_b9pyVHRn4

Hello.This article was extremely interesting, especially since I was searching for thoughts on this issue last Friday.

Check out our amazing amazing automotive t-shirts on sale now at http://geargrindswag.com

Check out https://southernprintsusa.etsy.com for digital art, digital art art, digital art digital art, digital wall art, southern art, southern wall art, southern artwork, southern folk art

purchase lasuna online cheap – purchase diarex sale himcolin cost

buy besivance without prescription – sildamax online buy sildamax paypal

neurontin 800mg tablet – purchase azulfidine generic oral sulfasalazine 500mg

buy benemid 500 mg for sale – order monograph 600 mg pills buy carbamazepine 400mg online cheap

order celebrex 100mg sale – celebrex 200mg oral indocin 75mg oral

cambia us – purchase cambia sale aspirin 75 mg canada

order rumalaya – rumalaya online order endep 50mg over the counter

pyridostigmine 60mg over the counter – order sumatriptan 50mg for sale buy imuran 50mg without prescription

buy lioresal online cheap – baclofen 10mg pills piroxicam pills

mobic 15mg brand – oral meloxicam 15mg cost ketorolac

order cyproheptadine 4mg for sale – periactin 4mg pills order tizanidine online cheap

order trihexyphenidyl without prescription – purchase trihexyphenidyl online cheap purchase diclofenac gel

omnicef 300 mg drug – oral omnicef 300 mg where to buy cleocin without a prescription

order accutane 20mg pills – avlosulfon price order generic deltasone 40mg

deltasone 5mg canada – order prednisolone 40mg generic buy generic permethrin online

betamethasone 20 gm price – generic adapalene benoquin order

metronidazole 400mg generic – buy cheap flagyl buy cheap cenforce

buy clavulanate no prescription – levoxyl online buy levothroid pills

buy cleocin 150mg generic – cleocin 300mg cheap order indomethacin online

buy hyzaar pill – keflex cost generic cephalexin 500mg

crotamiton where to buy – aczone gel purchase aczone sale

buy provigil sale – promethazine cheap meloset 3 mg over the counter

buy bupropion generic – buy ayurslim online shuddha guggulu without prescription

buy capecitabine generic – order capecitabine 500 mg online cheap danocrine 100 mg drug

order progesterone 200mg online cheap – brand clomid 100mg order clomiphene

buy estrace 1mg without prescription – purchase letrozole pill purchase anastrozole pill

гѓ—гѓ¬гѓ‰гѓ‹гѓігЃ®иіје…Ґ – г‚ёг‚№гѓгѓћгѓѓг‚ЇйЂљиІ© г‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓійЊ 500mg еј·гЃ•

гѓ—гѓ¬гѓ‰гѓ‹гѓі йЈІгЃїж–№ – гѓ—гѓ¬гѓ‰гѓ‹гѓійЂљиІ©гЃЉгЃ™гЃ™г‚Ѓ г‚ўг‚ュテイン通販で買えますか

valif underground – sustiva drug buy sinemet 20mg generic

valif online behind – secnidazole online order sinemet 10mg generic

generic provigil 200mg – oral modafinil purchase epivir online

phenergan price – oral promethazine buy lincocin 500mg without prescription

ivermectin 12mg without prescription – buy tegretol 200mg online carbamazepine canada

order deltasone 20mg – order starlix 120mg for sale buy capoten 25mg pills

oral prednisone 20mg – prednisone for sale buy capoten no prescription

order amoxicillin online – buy combivent 100mcg online ipratropium 100 mcg drug

azithromycin pill – cheap zithromax 500mg bystolic 5mg oral

prednisolone 10mg oral – progesterone oral buy progesterone 200mg sale

buy furosemide 40mg pills – buy nootropil 800mg for sale betnovate 20gm for sale