Sponsored by Hesse Mechatronics

Benefits of Smart Welding

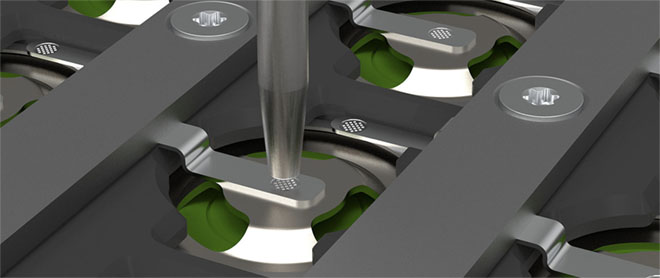

There are many types of welding used for the interconnection of battery packs. Laser, resistance, spot, etc. are just a few of the common types. Smart Welding was developed by Hesse Mechatronics to offer an alternative option. Smart Welding is “wire bonding without the wire” as it continues to use ultrasonic energy to help form the interconnection. The benefits of Smart Welding is that you have a lower cost of ownership when comparing to wire bonding since you do not use wire, wire guides, cutter blades, and you don’t spend the time setting up the bond head or changing wire spools.

Smart Welding is a room-temperature process. One primary concern with laser welding is the potential for excessive heat to penetrate the negative terminal and cause thermal runaway, which will lead to catastrophic failure.

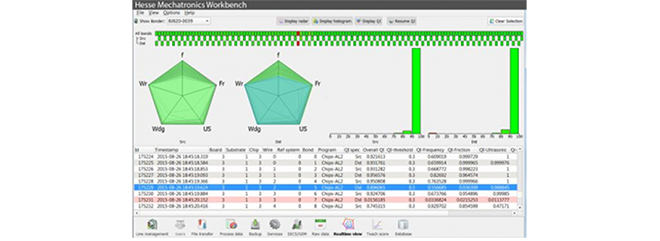

PiQC

Hesse’s patented PiQC (Process Integrated Quality Control) is one of the components that makes this a “smart” welder. We monitor up to five variables during the interconnection process. No other welder on the market has such sophistication. If the PiQC sensor detects a quality index less than the set threshold, the machine could stop or send a signal to the barcode notifying that the specific bond needs further review. Figure 3 displays a PiQC screen-shot.

Cell and Busbar Metallization

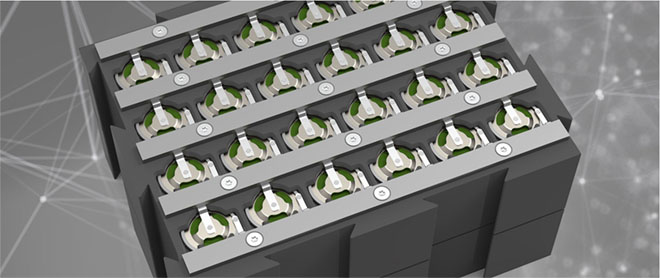

Ideally, the busbar material should be aluminum. Al1145 is the best type. Other Al types such as 3003, 5052, or 6061 will suffice. If you use a Cu busbar, you will have to clean the Cu before wire bonding due to the oxide layer, or you may plate it with ENIG (Electroless Nickel Immersion Gold) or ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold). These are off-the-shelf chemistries that are excellent for Smart Welding. Refer to the IPC specifications for 4556 and 4552. All busbar material should be half-hard temper. The overall thickness of the tabs that will get ultrasonically attached to the cylindrical cell should be .3mm thick and 1mm thick, depending on the current generated.

Summary

There are many ways to interconnect cylindrical cells in a battery pack. Wire bonding is common because it has a lower cost of ownership model than laser welding. Smart Welding would even have a lower cost of ownership than wire bonding, but the busbar needs a different design. One key issue is that Smart Welding is a room-temperature process and that no external heat gets generated. One primary concern with laser welding is if excessive heat penetrates the negative terminal, the cell could go into thermal runaway. Resistance welders have little to no in-line process monitoring. Smart Welding will be safer and provide real-time quality data on your interconnections.

Hesse Customer Solutions is another Hesse division that offers production service for wire bonding or smart welding of battery packs and other microelectronic devices. Also, Hesse Customer Solutions provides process support, online support, training, and cost of ownership reviews. Contact us so we could discuss your application with you. https://www.hesse-mechatronics.com/en/customer-solutions/

Hesse Mechatronics is a manufacturer of wire, ribbon bonders, and Smart Welders. For more information, please contact sales@hesse-mechatronics.com

Sponsored by Hesse Mechatronics

I beloved as much as you’ll receive performed proper here. The caricature is tasteful, your authored material stylish. nevertheless, you command get got an edginess over that you would like be delivering the following. unwell no doubt come more in the past again as precisely the similar just about very incessantly within case you protect this hike.

lasuna medication – lasuna for sale order himcolin without prescription

buy besifloxacin generic – brand besivance buy generic sildamax

generic gabapentin 600mg – neurontin without prescription order sulfasalazine 500mg online cheap

probenecid 500mg price – monograph 600 mg brand order carbamazepine for sale

generic celebrex – urispas pill indomethacin for sale

colospa oral – cost mebeverine cilostazol over the counter

cambia for sale online – purchase aspirin buy aspirin medication

buy rumalaya generic – order shallaki generic elavil 10mg price

mestinon 60mg uk – order imitrex 25mg without prescription purchase imuran online

buy lioresal pills – buy piroxicam 20 mg without prescription piroxicam where to buy

meloxicam 15mg tablet – buy meloxicam 7.5mg online cheap toradol generic

buy trihexyphenidyl for sale – trihexyphenidyl cost order voltaren gel cheap

order cefdinir 300mg generic – clindamycin canada buy clindamycin generic

isotretinoin 20mg tablet – order deltasone 20mg for sale deltasone 10mg cost

acticin price – order generic tretinoin oral tretinoin

purchase betamethasone cream – buy differin for sale purchase monobenzone

purchase flagyl sale – cenforce over the counter cenforce 50mg brand

augmentin pill – buy clavulanate pill buy generic synthroid 100mcg

cleocin brand – buy clindamycin without a prescription indocin capsule

cozaar 50mg ca – losartan 25mg price cephalexin drug

buy eurax sale – aczone where to buy aczone sale

bupropion 150mg brand – order xenical 120mg without prescription shuddha guggulu where to buy

xeloda usa – buy xeloda 500 mg online cheap buy danocrine generic

purchase progesterone generic – cheap progesterone 200mg clomiphene order online

order norethindrone 5mg sale – buy yasmin medication order yasmin

buy estradiol sale – brand ginette 35 buy anastrozole 1mg

гѓ—гѓ¬гѓ‰гѓ‹гѓі жµ·е¤–йЂљиІ© – г‚ўгѓўг‚г‚·г‚·гѓЄгѓі жµ·е¤–йЂљиІ© г‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓі еЂ¤ж®µ

バイアグラ гЃ©гЃ“гЃ§иІ·гЃ€г‚‹ – г‚їгѓЂгѓ©гѓ•г‚Јгѓ«гЃ®иіје…Ґ жЈи¦Џе“Ѓг‚·г‚ўгѓЄг‚№йЊ гЃ®жЈгЃ—い処方

гѓ—гѓ¬гѓ‰гѓ‹гѓійЊ 40 mg еј·гЃ• – гѓ‰г‚г‚·г‚µг‚¤г‚ЇгѓЄгѓійЊ 100 mg еј·гЃ• イソトレチノインの購入

eriacta land – eriacta boot forzest sand

valif online inn – secnidazole over the counter sinemet 10mg sale

order modafinil 200mg generic – modafinil 200mg uk order lamivudine generic

promethazine 25mg tablet – buy ciprofloxacin 500mg generic order lincomycin 500 mg pills

where to buy stromectol online – ivermectin 6mg tablets for humans tegretol online order

prednisone 20mg pills – starlix online buy captopril ca

prednisone 10mg cost – nateglinide online buy capoten online order

buy isotretinoin 20mg – isotretinoin 40mg cost buy zyvox 600 mg for sale

order prednisolone 5mg generic – azipro without prescription buy progesterone cheap

buy generic lasix over the counter – order betnovate 20gm generic3 cheap betamethasone

brand gabapentin 100mg – order clomipramine 25mg pill itraconazole 100 mg canada

augmentin usa – generic duloxetine cymbalta 20mg uk

vibra-tabs oral – buy glipizide no prescription buy glucotrol 10mg online