Leoni, a supplier of wiring systems, has jointly designed a wiring system with an automotive manufacturer to allow the automated production of cable sub-harnesses, such as for bumpers.

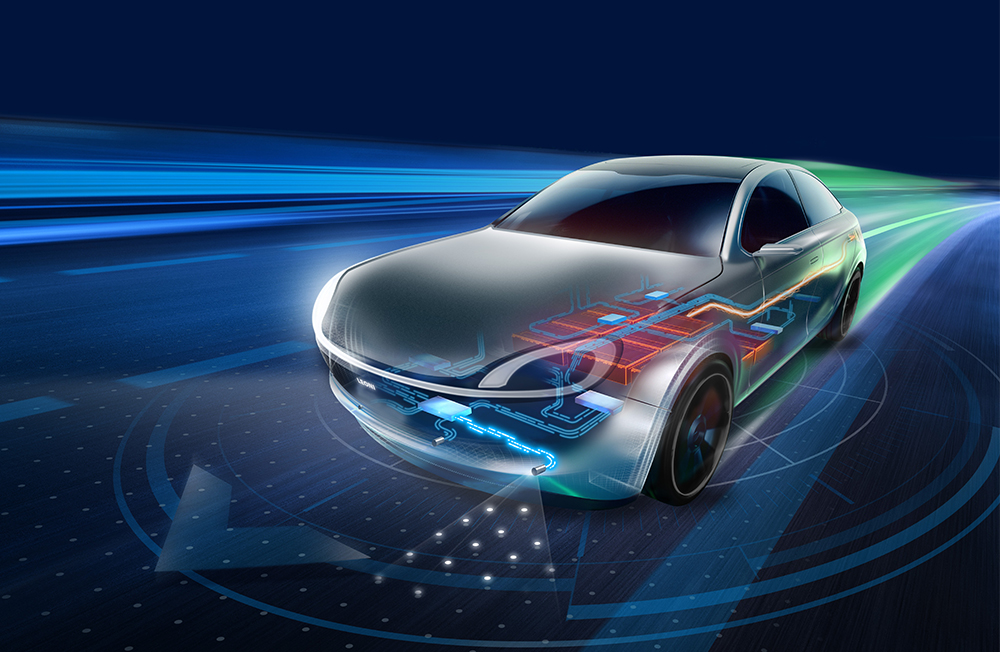

Leoni’s zonal architectures enable automotive manufacturers to reduce the total cost of ownership (TCO) of wiring systems and to reorganize production processes and supply chains. A zonal architecture divides the wiring system into zones, in which a zone controller will independently perform sub-tasks such as power distribution or data management to and from the sensors and actuators.

Within a few years, the first zonal architecture (zonal approach 1.0) will be mass-produced. Leoni is developing intelligent concepts and systems for the production of small, and later larger, cable harnesses. Initial analyses from current projects show that zonal architecture could decrease the weight of wire harnesses by 10%, the company said.

“Even in the development phase, the unavoidable short-term changes can be integrated more easily and thus more quickly into the overall architecture,” said Walter Glück, CTO of Leoni’s WSD Wiring Systems Division. “The same applies to model maintenance measures and ongoing development of the wiring system architecture in the event of a model change.”

Source: Leoni