Battery packs for e-vehicles are dropping in cost faster than ever predicted – this is one reason why the e-mobility markets are still growing at an expected 25% annual rate even over the next ten years.

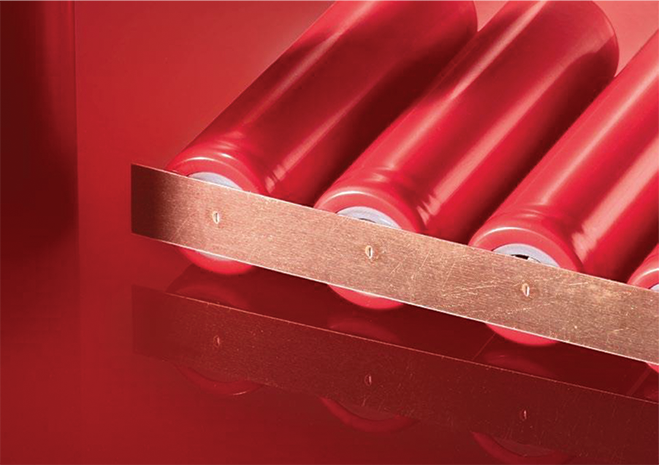

What is behind this drop in cost? It is not just the cost of cells that is coming down, but also the cost of battery pack assembly. Today’s prevailing cell type is the 21700 cylindrical cell, which offers an attractive combination of power, capacity, form factor flexibility, easy thermal management, safety, cost and – not least of all – availability. The most widely used assembly technology is wire bonding to connect the cells. It is extremely flexible and easy to automate, has very high yields and good repairability, and it is very economical: wire bonding makes up as little as around 1% of the total cost of a typical 75 kWh battery pack.

F&K Delvotec is proposing to push this even further down by its Laser Bonding process which combines the best features of conventional laser welding, such as tolerances to surface quality, with the superior robustness and handling advantages of ultrasonic bonding. One crucial advantage over conventional laser welding is, for instance, the guarantee for zero welding gaps and hence superior control of welding depth. In all, Laser Bonding has the potential to cut assembly cost by another 50%.