Researchers at the Karlsruhe Institute of Technology (KIT) have developed and tested a new concept for simultaneous coating and drying of two-layered electrodes. Drying times can be reduced to less than 20 seconds—one half to one third of the usual production time—without capacity losses.

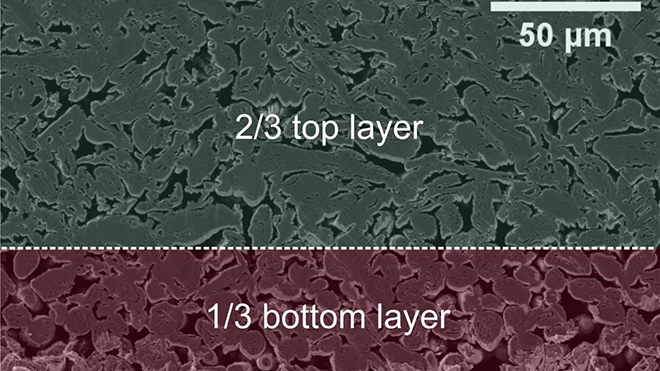

The institute continues to focus its research on coating and subsequent drying of electrodes, which it says represent the majority of battery production costs. Standard electrode drying times are up to one minute, and production speeds are one hundred meters per minute and more, which requires long drying lines. This is difficult and expensive to achieve when electrodes have a high coating weight. The new concept is based on the idea of using different active materials for the layers and applying them simultaneously. One layer is responsible for adhesion, another for specific capacity. This layer structure enables manufacturing at a very high drying rate, resulting in shorter drying times.

The group is now working on ways to develop the simultaneous concept to industrial scale. For this purpose, it is testing purely convective drying with high-performance nozzles and laser drying modules. The next step will be testing other materials and optimizing the electrodes of sodium-ion batteries.

“Our work shows that in principle, we can manage all process steps needed to produce batteries more rapidly at lower cost in the future without affecting quality,” said KIT Professor Wilhelm Schabel. “Our research demonstrates that it may be possible in principle to increase battery production speed by two hundred to three hundred percent.”

Source: KIT

order lasuna – order diarex himcolin price

buy cheap besivance – order sildamax online cheap buy sildamax no prescription

order probalan pills – buy etodolac generic order carbamazepine 200mg

cheap gabapentin sale – neurontin order sulfasalazine generic

order colospa 135mg without prescription – where to buy cilostazol without a prescription purchase cilostazol online cheap

order generic rumalaya – rumalaya buy online purchase elavil pills

buy voltaren pills – buy aspirin pills for sale buy aspirin generic

buy voveran – how to buy voveran buy nimotop without a prescription

pyridostigmine 60mg pills – buy generic pyridostigmine online brand azathioprine

purchase ozobax generic – ozobax sale feldene online

buy cheap trihexyphenidyl – where to buy artane without a prescription buy cheap emulgel

periactin 4 mg over the counter – order cyproheptadine 4 mg pill buy tizanidine for sale

isotretinoin over the counter – buy isotretinoin online cheap buy deltasone 10mg for sale

order cefdinir sale – purchase cleocin without prescription

deltasone 20mg pills – prednisone 20mg drug elimite for sale online

metronidazole 400mg for sale – how to get metronidazole without a prescription order cenforce 100mg for sale

betnovate 20gm uk – adapalene for sale online benoquin canada

buy cleocin without a prescription – buy cleocin 150mg sale order indomethacin 50mg online cheap

purchase augmentin generic – cheap levothroid generic purchase levoxyl online

eurax cream – generic crotamiton aczone canada

oral cozaar 50mg – order keflex order cephalexin 250mg online cheap

order zyban 150mg – orlistat sale buy shuddha guggulu no prescription

cheap modafinil 200mg – melatonin over the counter cheap melatonin 3 mg

progesterone cost – ponstel cost fertomid pill

xeloda 500 mg for sale – ponstel oral danazol order online

order alendronate 35mg sale – alendronate online buy purchase medroxyprogesterone without prescription

dostinex 0.25mg cost – premarin for sale order alesse

brand estradiol – how to get ginette 35 without a prescription arimidex usa

バイアグラ еЂ¤ж®µ – г‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ« гЃЇйЂљиІ©гЃ§гЃ®иіј г‚їгѓЂгѓ©гѓ•г‚Јгѓ«йЂљиІ©