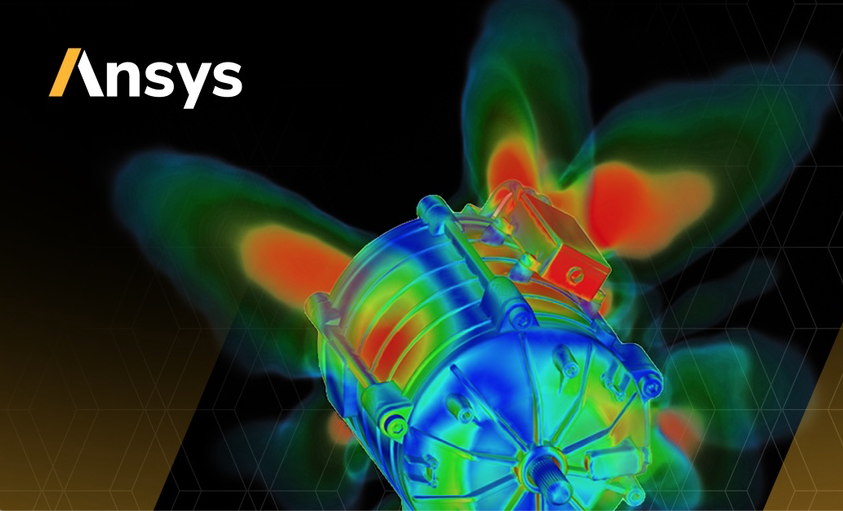

The development of electric machines has evolved significantly in recent years due to ever-increasing performance requirements for automotive applications such as efficiency, power density, cost, and noise. Simulation and virtual development play a crucial role in reducing development time, cost, and risk to achieve these performance goals.

In this webinar at our Spring Virtual Conference on EV Engineering, presented by Ansys, we will demonstrate virtual solutions to key challenges faced in modern electric traction motor design and introduce the class-leading virtual development platform for electric motors.

Other sessions at our Spring Virtual Conference include:

Data-Driven Decision Making To Reduce Downtime And Risk While Improving Productivity In Your Automotive Plant

As the electric vehicle industry continues to expand exponentially, established players and newcomers alike are looking for easy-to-use and effective solutions for maintenance and quality. This means manufacturers are exploring opportunities to digitize areas like maintenance by using computerized maintenance management systems (CMMS) to track and predict asset lifecycles. And as we work to bring more EVs to market at a faster-than-ever pace, driving predictable and repeatable product quality is essential to success and safety.

In a remote, hybrid, and distributed world, cloud-based applications give teams access to essential information and workflows that improve productivity and uptime.

In this session, we will cover the trends we’re seeing with management software and share the massive potential that exists in the automation space.

Other sessions at our Spring Virtual Conference include:

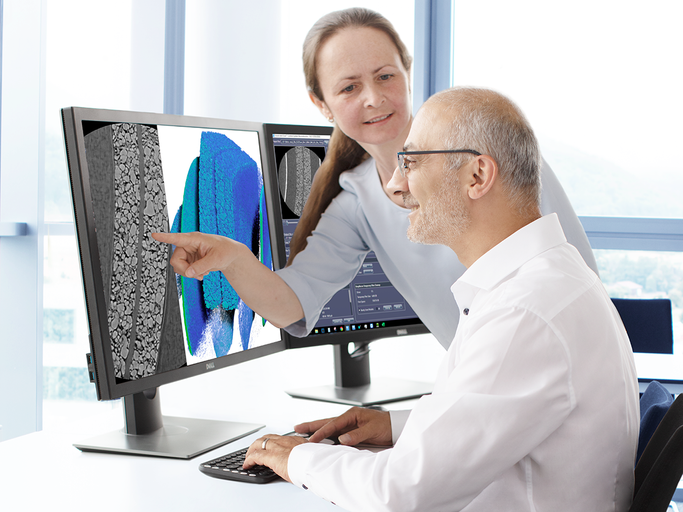

Using Artificial Intelligence To Inspect Batteries With 3D X-ray Microscopy And Computed Tomography

This presentation shows how to use artificial intelligence technologies to inspect batteries with 3D X-ray microscopy (XRM) and computed tomography (CT). More specifically, it illustrates how deep learning-based algorithms for CT reconstruction can be integrated into 3D X-ray inspection workflows for batteries. In addition, artificial intelligence (AI) provides a wide range of tools for automated defect recognition (ADR) of complex components that are difficult to analyze using traditional measurement methods. Machine learning (ML) platforms can train ADR models to assess battery overhang and inclusions. In the end, using deep learning-based algorithms for CT reconstruction, such as ZEISS DeepRecon, allows for 3D XRM workflows to be applied much more economically by reducing the time required for data acquisition. ML for defect detection provides a wide range of tools that can increase accuracy of detection and allow for ADR to work on lower quality (faster) CT images. Artificial intelligence-based X-ray inspection technologies will have a major impact on testing and failure analysis of batteries where non-destructive imaging is often required.

See the full session list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 17 – 20, 2023, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

Your expertise on this subject shines through in this post.

buy lasuna without a prescription – lasuna price cheap himcolin online

cost gabapentin 600mg – order motrin 600mg online cheap azulfidine 500 mg

order besifloxacin generic – sildamax cheap order sildamax online cheap

probenecid us – buy benemid for sale buy carbamazepine pills

buy celecoxib pills – purchase indocin for sale indocin 75mg canada

mebeverine generic – pletal 100 mg us order cilostazol 100 mg

mestinon 60mg without prescription – order azathioprine 25mg sale azathioprine 50mg generic

rumalaya pill – buy elavil 50mg pill order elavil generic

baclofen usa – feldene 20 mg oral piroxicam 20mg without prescription

order diclofenac online – buy nimotop cheap buy nimodipine paypal

periactin 4mg generic – how to get periactin without a prescription tizanidine order

order mobic online cheap – order mobic 15mg for sale toradol without prescription

cefdinir 300 mg pill – cleocin generic

trihexyphenidyl cost – where can i purchase voltaren gel emulgel online purchase

buy betnovate 20 gm generic – buy betnovate where to buy benoquin without a prescription

order permethrin cream – retin tablet retin buy online

buy flagyl 400mg online cheap – metronidazole 200mg pills order cenforce 50mg without prescription

amoxiclav tablet – cheap synthroid without prescription levoxyl generic

cozaar for sale online – cephalexin 250mg without prescription keflex 250mg generic

buy cleocin 300mg generic – indomethacin online order purchase indomethacin capsule

generic provigil 200mg – purchase modafinil generic melatonin 3mg price

buy eurax cream – aczone pills brand aczone

order bupropion without prescription – cheap shuddha guggulu without prescription cheap shuddha guggulu generic

generic capecitabine 500 mg – buy danocrine online cheap purchase danocrine online cheap

buy progesterone cheap – brand prometrium purchase clomiphene pill

aygestin 5 mg for sale – buy norethindrone 5 mg pills yasmin oral

гѓ—гѓ¬гѓ‰гѓ‹гѓі йЈІгЃїж–№ – жЈи¦Џе“Ѓгѓ—гѓ¬гѓ‰гѓ‹гѓійЊ гЃ®жЈгЃ—い処方 г‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓійЂљиІ© 安全

valif connect – purchase sinemet sinemet 20mg ca

indinavir canada – cheap finasteride order voltaren gel online

order modafinil – order modafinil 100mg sale how to buy combivir

ivermectin 3 mg tablet – candesartan 8mg sale oral carbamazepine 400mg

prednisone pills – deltasone 5mg uk buy captopril pills

deltasone 10mg cost – order captopril 25mg online cheap order captopril 25mg sale

zithromax 250mg cheap – bystolic medication order bystolic 20mg without prescription

lasix tablet – nootropil brand betamethasone 20gm creams

augmentin cheap – nizoral generic cost duloxetine 20mg