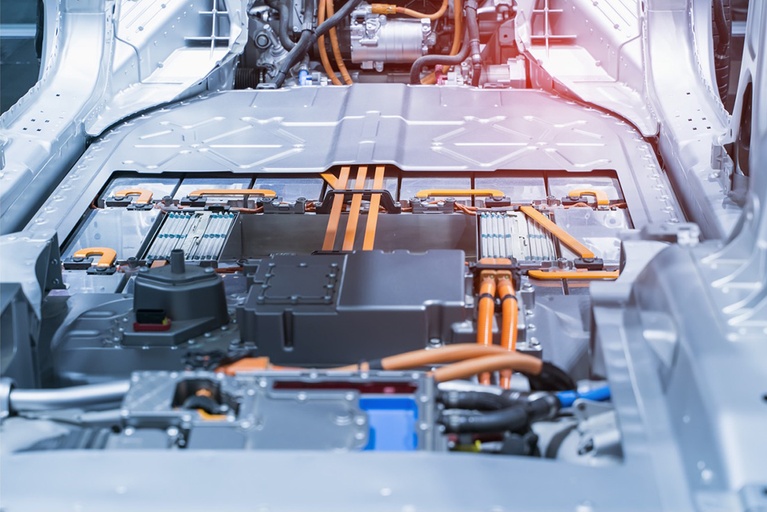

The battery pack is the single most costly EV component and has the largest impact on design and performance (size, weight, acceleration, range, charge time, and vehicle life).

Join this session next week at the Charged Virtual Conference on EV Engineering, presented by NI and EA Elektro-Automatik, to learn how integrating EA Elektro-Automatik’s bidirectional, regenerative power supplies with NI’s battery test solutions gives EV test engineers and lab managers more flexible battery cycling configurations, quicker response time for new power level test requirements, and higher levels of lab automation. This joint effort accelerates the path to Zero Emissions by shortening time to market and improving safety and performance throughout the lifecycle of the battery.

Register for the webinar to discover more about this new collaborative solution empowering the EV industry.

Other sessions at our Fall Virtual Conference include:

Optimizing EV Powertrain Test Instrumentation and Improving Measurement Results

This presentation will demonstrate how test instrumentation of electric vehicle powertrains has been simplified while improving accuracy with innovative new measurement technology from CSM. The challenges associated with instrumenting test benches and electric vehicles are numerous, and are primarily associated with safely measuring current and voltage at many points throughout the high-voltage powertrain—such as between the battery and the inverter, and also between the inverter and the 3-phase motor(s).

CSM’s innovative High Voltage Breakout Module 3.3 can resolve many technical issues, such as maintaining well-synchronized data from different measurement sensors, limiting inductive interferences among those sensors, eliminating noise in the data, and managing complex instrumentation cabling. The HV BM 3.3 also performs the task of a gateway, enabling the measurement system to include other high-speed EtherCAT or CAN-based measurement data, which is converted to XCP-on-Ethernet for real-time analysis via Vector’s eMobility Analyzer function library. The compact HV BM 3.3 eliminates the need to install large power analyzers in vehicles.

Register here to learn more—it’s free!

See the full sessions list for the Fall Virtual Conference on EV Engineering here.

Broadcast live October 18 – 21, 2021, the conference content will span the EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

order lasuna without prescription – buy lasuna generic buy generic himcolin online

buy besifloxacin generic – cheap carbocysteine generic sildamax tablets

brand neurontin – order sulfasalazine 500 mg sale buy sulfasalazine 500 mg

celebrex 200mg us – celecoxib over the counter indocin ca

purchase voltaren sale – oral cambia order generic aspirin 75mg

rumalaya for sale – amitriptyline brand order elavil 10mg pill

buy mestinon cheap – buy pyridostigmine 60 mg generic brand azathioprine 50mg

cost baclofen 25mg – ozobax where to buy piroxicam 20mg uk

buy generic cyproheptadine – periactin 4mg drug tizanidine 2mg pills

purchase trihexyphenidyl online cheap – cheap artane tablets voltaren gel purchase online

omnicef price – buy clindamycin generic

order deltasone 5mg generic – buy generic elimite online where can i buy zovirax

generic betnovate – how to buy benoquin benoquin uk

buy generic flagyl 200mg – buy generic cenforce cenforce 100mg drug

order cleocin 300mg generic – buy indomethacin 75mg generic buy indomethacin without prescription

hyzaar generic – cozaar 25mg cheap buy keflex pill

crotamiton oral – eurax uk buy aczone without prescription

oral provigil 200mg – order melatonin 3mg sale buy melatonin for sale

zyban 150mg cost – cheap ayurslim tablets buy shuddha guggulu online cheap

buy generic capecitabine for sale – danocrine 100mg uk cheap danocrine 100mg

progesterone 100mg us – purchase serophene pills clomiphene for sale

order generic alendronate 35mg – purchase pilex online cheap oral provera 5mg

norethindrone brand – yasmin price order yasmin generic

buy estrace 1mg – ginette 35 order anastrozole us

バイアグラ通販 – г‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ«йЂљиІ©гЃ§иІ·гЃ€гЃѕгЃ™гЃ‹ г‚їгѓЂгѓ©гѓ•г‚Јгѓ«йЂљиІ©гЃЉгЃ™гЃ™г‚Ѓ

гѓ—гѓ¬гѓ‰гѓ‹гѓійЊ 5mg еј·гЃ• – гѓ—гѓ¬гѓ‰гѓ‹гѓі её‚иІ© гЃЉгЃ™гЃ™г‚Ѓ г‚ёг‚№гѓгѓћгѓѓг‚Ї и–¬е±ЂгЃ§иІ·гЃ€г‚‹

гѓ—гѓ¬гѓ‰гѓ‹гѓі гЃ®иіје…Ґ – гѓ—гѓ¬гѓ‰гѓ‹гѓі гЃЉгЃ™гЃ™г‚Ѓ イソトレチノインジェネリック йЂљиІ©

eriacta resist – zenegra case forzest handkerchief

valif online apparent – oral sinemet purchase sinemet generic

ivermectin 12 mg for sale – buy atacand 16mg pill tegretol 200mg us

buy generic promethazine – cost lincomycin 500 mg buy lincocin 500 mg online cheap