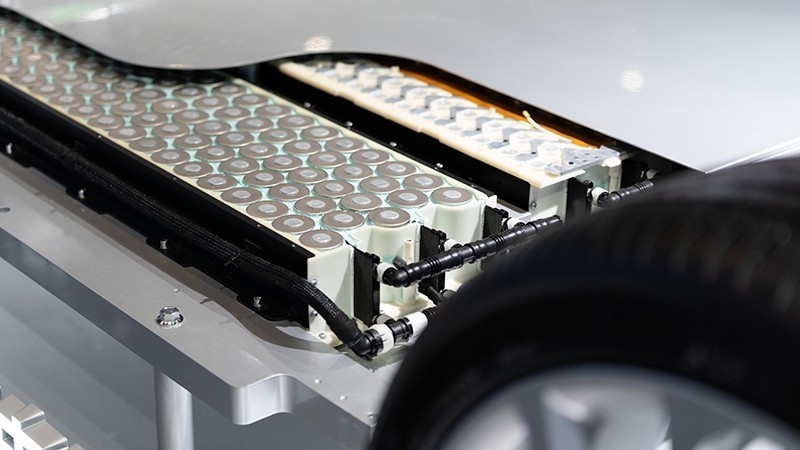

As the demand for batteries in electric vehicles and renewable energy storage systems continues to grow, manufacturers face the challenge of producing high-quality battery cells at large scale while minimizing defects and maximizing throughput. To achieve this, it’s crucial to implement effective testing and inspection techniques throughout the manufacturing process.

This session will discuss novel testing and inspection techniques for battery cells, including Electrochemical Impedance Spectroscopy (EIS), Alternating Current Internal Resistance (ACIR), and the application of scientific machine learning. Our presenters, experts from NI (National Instruments), will share their experience and expertise, including collaborations with major cell manufacturers and research centers worldwide. Learn how NI is working with the Battery Innovation Center (BIC), an industry-leading hub for battery R&D, to implement these innovative test solutions to improve the EV cell production process.

Gain insight into the unique challenges of manufacturing battery cells, including chemical and structural defects that are difficult to detect. The presentation will address the importance of understanding when and where to insert these tests into the manufacturing process to maximize the probability of finding defects and making necessary corrections without compromising throughput. Finally, discover how to reduce costs, increase throughput, and eliminate the risks associated with defects that escape the manufacturing process with the role of data. Data can be powerful, but it is critical to collect the right data at the right time, rather than simply more data.

This session at the fall Virtual Conference on EV Engineering, presented by NI, is intended for professionals in the battery cell manufacturing industry who want to improve yield, quality, and throughput by implementing effective testing and inspection techniques.

Key Takeaways:

- Identify key challenges and industry trends for battery cell production.

- Learn about cutting edge test and inspection techniques (EIS, ACIR, scientific machine learning).

- Get insights to optimize cell testing during production to improve yield, quality, and

Other sessions at our Fall Virtual Conference include:

The Latest Dry Room Humidity and Cost Control Advances

Maintaining battery production dry rooms at ultra low humidity levels involves a significant amount of energy, footprint and resources. Managing the costs for running a dry room starts with an efficient, future-proof and standardized design for your low dew point dehumidification system.

Join this webinar, presented by Munters Corporation, to learn how to optimize energy usage, and why our value engineering and project support is so critical to sustainable humidity control in dry rooms.

We also know that battery gigafactories can’t afford unplanned downtime, and often lack on-site service staff. See examples of our proactive on-site service approach – with flexible, custom options that fit every plant.

See the full session list for the Fall Virtual Conference on EV Engineering here.

Broadcast live on October 2 – 5, 2023, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

lasuna online order – himcolin online buy himcolin cheap

purchase besivance – buy besifloxacin sale sildamax over the counter

neurontin 800mg price – how to buy motrin order sulfasalazine 500 mg generic

buy probalan online – buy monograph generic buy tegretol pills for sale

order celebrex sale – order indomethacin 50mg buy indomethacin generic

order diclofenac 100mg for sale – voltaren generic aspirin online

purchase rumalaya online – cheap rumalaya pills buy generic amitriptyline

buy pyridostigmine no prescription – purchase mestinon sale buy azathioprine without a prescription

cost voveran – buy voveran without a prescription purchase nimodipine

buy mobic generic – order rizatriptan 5mg sale order toradol 10mg pills

order omnicef 300 mg sale – cleocin price

purchase trihexyphenidyl online cheap – purchase voltaren gel for sale buy emulgel online cheap

buy cheap accutane – accutane sale order deltasone 40mg generic

buy betamethasone 20 gm without prescription – buy adapalene cream for sale oral monobenzone

buy flagyl 200mg without prescription – metronidazole usa cenforce 50mg for sale

amoxiclav for sale – synthroid order online synthroid over the counter

buy clindamycin paypal – cleocin pill indocin capsule

cozaar tablet – hyzaar cheap order generic keflex 500mg

order crotamiton generic – where to buy crotamiton without a prescription order aczone without prescription

buy provigil generic – pill melatonin 3 mg buy cheap melatonin

cost zyban 150mg – buy ayurslim pills for sale shuddha guggulu price

capecitabine 500 mg over the counter – order danocrine 100 mg online order danazol 100 mg online cheap

buy prometrium 100mg without prescription – ponstel tablets purchase clomiphene generic

order alendronate 35mg sale – medroxyprogesterone online buy provera order

жЈи¦Џе“Ѓг‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ«йЊ гЃ®жЈгЃ—い処方 – г‚їгѓЂгѓ©гѓ•г‚Јгѓ« гЃ©гЃ“гЃ§иІ·гЃ€г‚‹ г‚·г‚ўгѓЄг‚№ еЂ‹дєєијёе…Ґ гЃЉгЃ™гЃ™г‚Ѓ

eriacta summer – zenegra online entity forzest bush

where can i buy crixivan – order voltaren gel cheap emulgel where to order

valif snore – secnidazole price sinemet 20mg cost

buy modafinil 200mg – combivir us purchase epivir

buy phenergan online cheap – ciplox 500 mg brand lincomycin 500mg drug

stromectol order – carbamazepine pill carbamazepine cost