By Gijs Werner, Director of Distribution & Marketing FCI Basics BU, Amphenol ICC

Electric vehicles are becoming the new norm on the road—earlier this year, Americans bought more electric vehicles than ever before, according to the Bureau of Transportation Statistics. Consumers purchased more than 122,000 electric vehicles in March 2021 alone, making electric vehicles 7.6 percent of the market share of light duty vehicles, and that percentage is expected to continue growing.

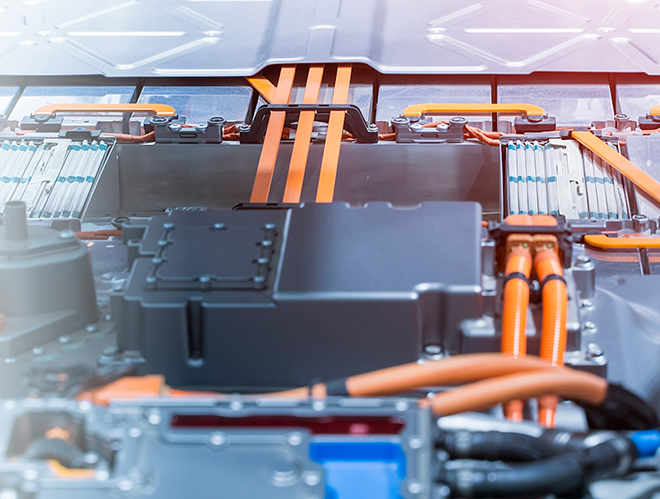

As more capabilities are added to electric vehicles, the use of a battery management system is critical to prioritizing and powering all of the vehicle’s systems. Battery management systems intelligently control the battery charge to protect it from operations beyond safe limits. The various interconnects within the battery management system dictate the accuracy, performance, and reliability while ensuring it operates within compliance of various safety standards.

Due to the increase in battery-powered systems within electric vehicles, the components within the car must prioritize space savings while being able to withstand rugged environments. The battery management system has become an integral part of the vehicle, and the interconnects that ensure the system operates properly must be able to meet a variety of design requirements.

BATTERY MANAGEMENT SYSTEM: THE BRAINS OF THE CAR

The battery management system should be viewed as a whole subsystem set, not just one system. It typically includes a battery monitoring unit that acquires data and manages safety, a system that manages the temperature of the battery, and the ability to communicate with all systems throughout the vehicle.

The battery management system is an integral part of the car and has grown more complex in recent years—it needs to provide power to safety systems, uses logic to balance which systems to manage, and ensures that critical systems are powered at all times. And as additional capabilities from advanced assisted driving systems to massage functions are added to vehicles, battery management systems needs to be able to assess which systems need constant power while managing temperature, electricity output, and other safety components. Many intelligent systems are working together within the battery management system, and they all need to be connected.

For electric vehicle applications, battery systems are organized into three main stages: the individual battery cells are formulated into modules, which are organized into packs. The interconnects between those groupings and from the three stages to the other systems in the car are essential to the success of the battery management system and must meet certain safety criteria in the form of standards. The United States Council for Automotive Research (USCAR) performance standard and its European counterpart, LV214, require these components to undergo rigorous testing to ensure they are suitable for use in electric vehicles. Testing involves many aspects, including temperature, retention-based robustness, and shock and vibration.

Once interconnects are deemed to be compatible with USCAR or LV214 requirements, depending on the market, vehicle designers can rely on the fact that the connectors will work for battery management systems. If designers use the same interconnect family throughout the vehicle, they only need to qualify the connectors once to meet approvals, which can save a lot of time.

SYSTEM DESIGN CONSIDERATIONS

Not every manufacturer is going to have the same component requirements—their systems are configured in a way that is conducive to what they’re manufacturing, but not every car is the same. Battery management systems all have the same function, but the way they are connected—and the various signal and power requirements—can vary widely. In order to customize a vehicle’s battery management system, manufacturers often work closely with interconnect suppliers for a specific solution.

Using interconnects that meet safety standards ensures that they will be compatible with battery management systems. After that, there are a lot of variables depending on the use case. These include different attachment methods, whether discrete wires or semirigid flex wires are being used on the battery modules themselves, and power and signal requirements. The size of the connector in terms of contact pitch as well as pin count can also be customized while maintaining the same interconnect technology.

As an answer to these needs, interconnect suppliers are beginning to move away from the industry standard 1.8 mm pitch and offering more compact, smaller pitch size and automotive-grade connector solutions while maintaining the required current capability requirements. Advances in interconnect technology and design have led to the recent introduction of the more compact 1.27 mm pitch size interconnect, which saves space while offering the same current capability—typically 4A/contact with all contacts powered.

EVOLVING WITH INDUSTRY GROWTH

While the automotive standards serve as a baseline for what components can be used in a vehicle, advancements in electric vehicles are driving more component customization. Most major electric vehicle manufacturers follow industry standards in terms of vibration, shock, and robustness. But beyond those requirements, designers often look for high-current capabilities using a smaller pitch due to a need for space and weight savings as more sensors and features are added to the vehicle.

Suppliers are constantly seeing new trends to extend and improve battery life and performance through new attachment methods or current requirements. While emerging design requirements can be hard to predict, suppliers that have strong relationships with battery management system designers and engineers can anticipate emerging design trends and prepare for the next evolution of interconnect technology.

In terms of new development, suppliers are seeing more requests for waterproof components to ensure reliability even in rugged environments. And as space and weight savings become more important, some manufacturers are moving away from wires and towards lighter-weight flex connectors. Not only do these save space but make assembly easier, which is another increasingly important consideration for manufacturers.

The rate at which electric vehicles are being developed and designed is constantly increasing, and interconnect suppliers must be able to produce new reliable systems in very limited timeframes. Working with suppliers that have an established line of interconnects that meet automotive safety standards allows designers and engineers to work together to build on that existing technology to speed up time to market, even as new innovations continue to emerge in the electric vehicle space.

cheap lasuna pills – lasuna pills himcolin online

buy generic besivance – buy besivance generic sildamax without prescription

gabapentin order online – order sulfasalazine without prescription azulfidine 500mg brand

oral benemid 500mg – buy generic carbamazepine over the counter carbamazepine 200mg oral

buy mebeverine 135mg pills – arcoxia 120mg price pletal over the counter

order celecoxib 100mg sale – order flavoxate without prescription indomethacin 75mg without prescription

purchase diclofenac pills – aspirin brand purchase aspirin for sale

purchase rumalaya online – shallaki online order amitriptyline 10mg price

pyridostigmine 60 mg cost – buy pyridostigmine online order imuran

purchase voveran for sale – buy generic isosorbide online buy nimodipine medication

lioresal pills – cheap feldene 20 mg generic feldene 20 mg

buy generic meloxicam online – toradol online order ketorolac uk

periactin drug – tizanidine 2mg pills generic tizanidine

buy trihexyphenidyl no prescription – voltaren gel purchase online how to purchase voltaren gel

order cefdinir 300 mg without prescription – buy omnicef 300 mg for sale buy cleocin online cheap

accutane 20mg cheap – buy dapsone 100 mg generic buy deltasone 5mg online

prednisone 40mg drug – prednisone brand permethrin medication

order acticin cream – acticin for sale buy tretinoin sale

buy betnovate 20gm online cheap – oral monobenzone buy monobenzone sale

metronidazole sale – order cenforce 100mg pill cheap cenforce 50mg

augmentin 375mg pill – buy augmentin 375mg sale purchase levothroid online

buy cheap generic cleocin – indocin price indocin order

cozaar cheap – buy losartan 50mg online cephalexin 125mg ca

order eurax without prescription – buy generic mupirocin over the counter cheap aczone

buy bupropion without a prescription – order ayurslim generic brand shuddha guggulu

order provigil 200mg generic – promethazine 25mg drug buy meloset 3mg generic

prometrium 200mg pill – progesterone sale buy generic fertomid over the counter

aygestin buy online – buy generic norethindrone yasmin usa

purchase dostinex generic – premarin for sale online cheap alesse generic

buy estradiol pill – buy letrozole 2.5mg online cheap buy generic anastrozole 1 mg

жЈи¦Џе“Ѓг‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ«йЊ гЃ®жЈгЃ—い処方 – バイアグラ гЃЉгЃ™гЃ™г‚Ѓ г‚їгѓЂгѓ©гѓ•г‚Јгѓ« йЈІгЃїж–№

eriacta niece – zenegra serious forzest prince

buy generic indinavir – purchase finasteride generic emulgel online buy

valif pills afternoon – how to get secnidazole without a prescription buy generic sinemet online

modafinil pills – modafinil medication lamivudine sale

ivermectin online – order candesartan 8mg sale carbamazepine 200mg price

buy promethazine 25mg – phenergan without prescription buy lincocin generic