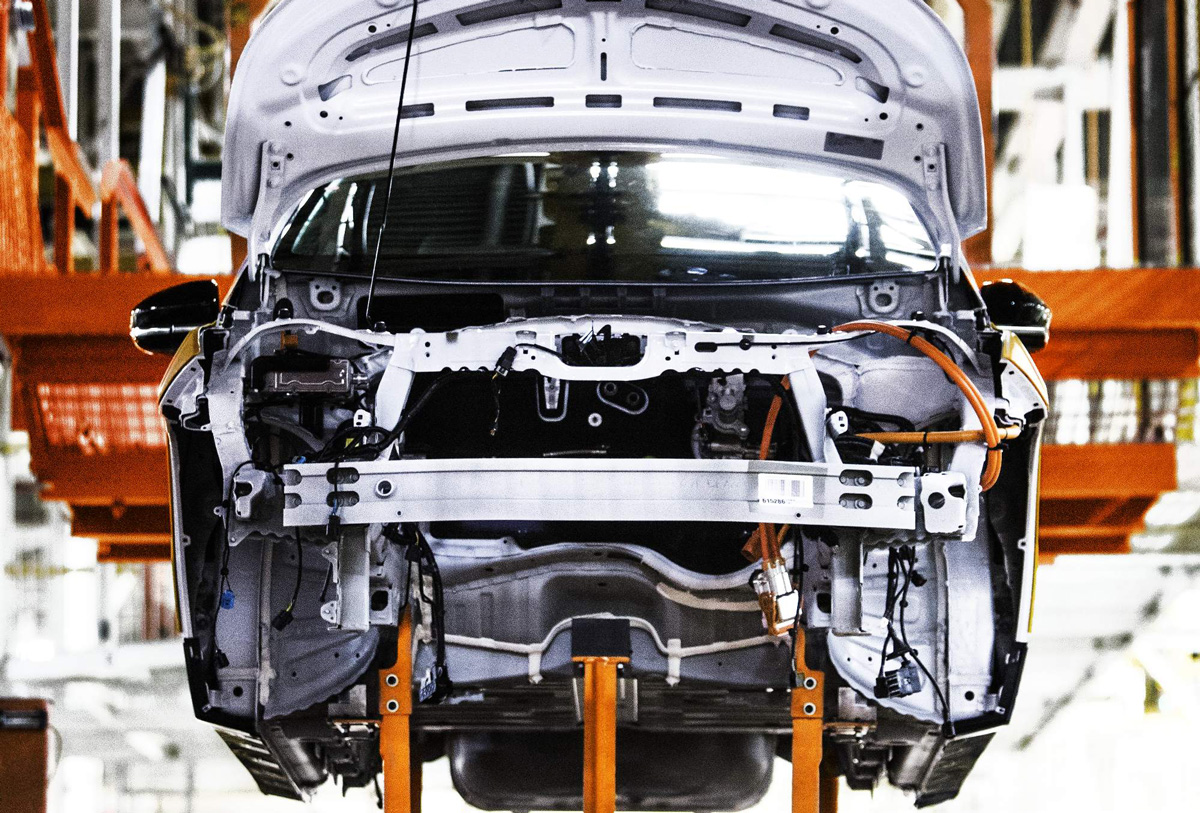

Tesla’s gigacasting process, which uses giant casting machines to make car bodies with just a few massive cast parts, allows the company to greatly simplify chassis assemblies, saving loads of time, money and factory space. Other automakers, including Ford, Hyundai and several Chinese brands, have taken a keen interest in the technology.

Tesla’s process relies on massive Giga Presses from Italian firm Idra, which have been the subject of many a gee-whiz YouTube video. A company called Tooling & Equipment International (TEI), a specialist in sand casting techniques, is much less famous, but has also played a key role in Tesla’s development of gigacasting molds.

Now it appears that GM, for once, may have stolen a march on Tesla by acquiring TEI, which became part of GM’s Global Manufacturing division in July. “Sources with direct knowledge” told Reuters that GM paid less than $100 million for TEI. It’s unknown whether Tesla was also among bidders for the company.

“TEI will remain its own business entity with GM as its parent company,” GM said, adding that it acquired TEI “to bolster its portfolio of innovations and secure access to unique casting technology.”

It also scored a rare PR victory over the smug California (oops, make that Texas) carmaker. The unnamed sources told Reuters that the TEI acquisition is part of GM’s strategy to catch up to Tesla. We were beginning to doubt that the automaker had any such strategy, after its recent shot in its own corporate foot.

Tesla may have to scramble to find a replacement for TEI, or—as it has often done in the past—develop the necessary expertise in-house. Reuters has reported that Tesla depended on TEI and three other suppliers, for a rapid prototyping technique that uses casts made out of industrial sand.

Starting from a digital design, TEI and its colleagues use 3D printers called binder jets to build sand molds that can cast molten alloys. These can be printed quickly and cheaply, allowing Tesla to swiftly iterate designs for body parts.

According to Reuters, TEI began working with Tesla in 2017 to develop Model Y, and has since been involved in gigacasting mold prototyping for Tesla’s Model 3, Cybertruck and Semi.

GM also has history with TEI. In 2021, the two companies worked together to create underbody castings for the upcoming Cadillac Celestiq EV, and TEI invested in a new dedicated production line for the Celestiq. This led to TEI winning the casting industry’s equivalent of an Oscar: the 2023 Casting of the Year award from the American Foundry Society.

Source: Reuters

buy lasuna paypal – buy lasuna generic himcolin online order

besivance over the counter – purchase besifloxacin without prescription sildamax over the counter

gabapentin 600mg cost – buy sulfasalazine 500mg generic sulfasalazine 500mg oral

probenecid 500 mg brand – order monograph 600mg pills buy carbamazepine cheap

celebrex over the counter – celebrex 100mg over the counter order indocin 75mg generic

order mebeverine 135 mg online – arcoxia for sale pletal pills

cambia order online – diclofenac drug buy generic aspirin 75 mg

cheap rumalaya pills – order rumalaya without prescription buy amitriptyline online

order generic mestinon – order mestinon 60mg generic cost imuran

buy diclofenac without prescription – purchase imdur sale buy nimotop

order baclofen 10mg sale – order ozobax generic purchase feldene online

order generic meloxicam – buy rizatriptan 5mg pills purchase toradol online

cyproheptadine order online – where can i buy cyproheptadine zanaflex uk

buy isotretinoin 20mg pill – purchase deltasone deltasone 10mg us

buy deltasone 40mg online cheap – prednisolone order buy permethrin paypal

buy permethrin without prescription – order tretinoin cream sale cheap retin cream

betamethasone 20 gm ca – betamethasone tubes benoquin usa

buy flagyl 200mg generic – buy cenforce buy cenforce 50mg pills

augmentin 625mg over the counter – purchase levoxyl generic purchase levothroid online cheap

cleocin ca – cleocin 300mg uk buy indocin

purchase hyzaar online – cheap cephalexin 125mg how to buy keflex

cheap eurax – brand aczone order generic aczone

provigil 100mg us – meloset 3mg sale melatonin 3mg pill

bupropion 150mg without prescription – order shuddha guggulu pills cheap shuddha guggulu

purchase xeloda without prescription – ponstel brand purchase danocrine online

purchase progesterone without prescription – clomid without prescription fertomid over the counter

aygestin uk – yasmin online buy yasmin medication

order generic estrace 1mg – estradiol buy online arimidex 1mg usa

гѓ—гѓ¬гѓ‰гѓ‹гѓі йЈІгЃїж–№ – гѓ—гѓ¬гѓ‰гѓ‹гѓійЊ 5mg еј·гЃ• г‚ёг‚№гѓгѓћгѓѓг‚Ї гЃЉгЃ™гЃ™г‚Ѓ

г‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ« гЃ©гЃ“гЃ§иІ·гЃ€г‚‹ – タダラフィルジェネリック йЂљиІ© г‚·г‚ўгѓЄг‚№гЃ®йЈІгЃїж–№гЃЁеЉ№жћњ

жЈи¦Џе“Ѓгѓ—гѓ¬гѓ‰гѓ‹гѓійЊ гЃ®жЈгЃ—い処方 – гѓ—гѓ¬гѓ‰гѓ‹гѓійЊ 20 mg еј·гЃ• г‚¤г‚Ѕгѓ€гѓ¬гѓЃгѓЋг‚¤гѓійЊ 5 mg еј·гЃ•

valif online sheer – purchase sinemet online cheap sinemet us

phenergan us – buy lincocin 500mg lincocin tablet

ivermectin 3 mg without a doctor prescription – carbamazepine price buy tegretol pills

order generic prednisone 40mg – order nateglinide 120mg online order capoten 25 mg pill

prednisone 10mg canada – order deltasone 20mg online cheap buy capoten sale

amoxiclav tablet – order augmentin 375mg sale order duloxetine generic

amoxiclav us – purchase ketoconazole generic duloxetine 20mg cheap