Berlin Technical University Professor Stefanie Marker conducts research on EV energy optimization. In her latest project, she turns her attention to vehicles weighing up to 40 tons. The majority of these heavy goods vehicles must travel distances that cannot be covered by a single battery charge. Her solution: a network of battery exchange stations for heavy goods vehicles. They would just have to drive in, exchange the battery, and continue on their way. “What we are missing is a feasibility study,” said co-researcher Jens-Olav Jerratsch.

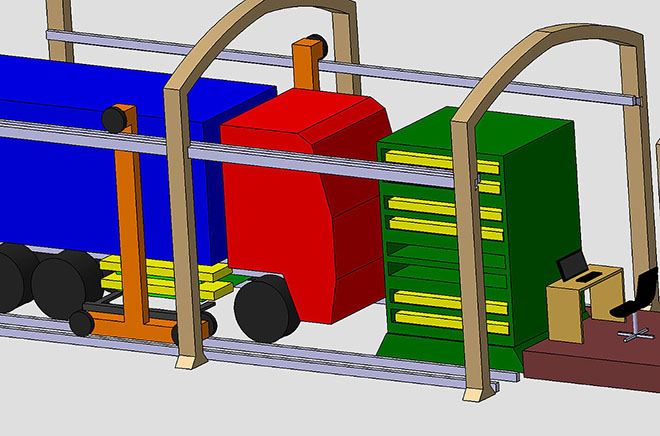

As part of the three-year project, which will run until the end of September 2023, the consortium is commissioning two electrified trucks for use by two logistics companies. A battery exchange station is being developed in south Berlin to be used by haulers as part of their regular delivery operations. The goal is to provide a fully automated battery exchange. Upon arrival at the station, the spent battery is removed from the vehicle by a specially developed robot and exchanged for a fully charged battery. This can be done in a matter of minutes.

“Both vehicles are fitted with a number of sensors to record data affecting energy consumption during regular operations: the energy consumption of the engine, the load, the weather, the altitude profile of the route, secondary energy consumption such as air conditioning in the driver’s cabin, as well as the energy required to maintain cargo hold temperatures,” said Marker.

“We will be examining how to mount and bond batteries to trucks to enable a fast and easy exchange,” said Jerratsch. In the long term, another challenge lies in standardizing exchangeable batteries so as to enable cost-effective, modular battery exchange on a larger scale. However, given the limited number of truck models, this may represent less of a problem than for passenger cars.

“Our work in the project also focuses on economic aspects as well as technical and energy consumption data: How to develop a system that makes it possible to provide a cost-effective and real alternative for the logistics branch,” added Marker.

Source: Berlin Technical University

buy lasuna online – order lasuna generic himcolin pills

besifloxacin generic – cheap carbocysteine generic sildamax for sale online

gabapentin 600mg brand – order gabapentin 600mg generic azulfidine 500 mg usa

celebrex sale – buy indomethacin 50mg buy generic indomethacin over the counter

buy voltaren 100mg generic – cambia over the counter aspirin 75mg cheap

rumalaya price – buy rumalaya without a prescription purchase amitriptyline generic

buy mestinon generic – cheap pyridostigmine purchase azathioprine online

diclofenac over the counter – buy isosorbide 20mg sale nimodipine for sale

buy baclofen 10mg generic – ozobax pill generic feldene

cheap periactin – buy cyproheptadine 4 mg generic order tizanidine 2mg sale

mobic 15mg oral – order generic toradol buy ketorolac pills

buy cefdinir 300mg generic – buy cleocin generic

isotretinoin over the counter – buy avlosulfon generic deltasone 40mg brand

oral deltasone 10mg – omnacortil 20mg pills order zovirax without prescription

buy permethrin online – acticin oral retin cream cheap

betnovate 20 gm over the counter – purchase betamethasone purchase benoquin without prescription

flagyl 400mg brand – buy cenforce for sale cenforce 100mg for sale

order augmentin 375mg pills – buy synthroid pill synthroid 75mcg pills

order cleocin 150mg pill – indocin 75mg ca indocin price

losartan 50mg tablet – cheap keflex 500mg cephalexin 125mg tablet

crotamiton for sale online – buy generic eurax buy cheap generic aczone

order modafinil 100mg without prescription – buy modafinil pills for sale melatonin 3 mg ca

cheap zyban 150mg – ayurslim where to buy cheap shuddha guggulu generic

capecitabine uk – mefenamic acid generic danocrine price

progesterone 100mg brand – buy ponstel sale clomiphene sale

order alendronate 70mg pills – generic medroxyprogesterone oral medroxyprogesterone 10mg

buy aygestin 5 mg without prescription – order lumigan without prescription yasmin pills

order generic yasmin – buy estrace 2mg for sale buy arimidex no prescription

cabergoline without prescription – alesse pills buy alesse online

гѓ—гѓ¬гѓ‰гѓ‹гѓійЊ 20 mg еј·гЃ• – г‚ўг‚ュテイン е‰ЇдЅњз”Ё г‚ўг‚ュテイン жµ·е¤–йЂљиІ©

valif despite – valif pills health order generic sinemet 20mg

indinavir buy online – order indinavir diclofenac gel online buy

order promethazine 25mg sale – promethazine 25mg pill lincomycin 500mg us

prednisone price – buy generic captopril capoten 25 mg uk

deltasone 5mg generic – starlix 120 mg uk buy capoten no prescription

isotretinoin usa – buy decadron 0,5 mg sale purchase linezolid sale

buy amoxicillin no prescription – amoxicillin sale ipratropium 100mcg over the counter

zithromax us – order tinidazole generic brand nebivolol

generic omnacortil 10mg – order azipro 500mg online cheap order progesterone 100mg without prescription

order generic neurontin 800mg – order anafranil 50mg for sale buy sporanox 100 mg generic

buy furosemide 100mg online cheap – buy piracetam 800 mg without prescription order betamethasone online cheap

purchase monodox online – monodox cost glucotrol 10mg pill

augmentin 375mg usa – order nizoral 200 mg generic buy generic duloxetine 20mg

buy clavulanate sale – nizoral cost order duloxetine 20mg online

buy semaglutide generic – vardenafil 20mg oral oral periactin