Sponsored by bdtronic

Electromobility is the future of mobility. Alongside the electric motor, the high-voltage battery or high-voltage storage unit is the heart of an electric car or hybrid vehicle. It supplies the electric motor with power and also serves as an energy storage device. The battery pack consists of several battery modules, which in turn consist of a large number of battery cells. There is a wide variety of applications for dispensing, plasma and heat staking technologies for battery manufacturing.

Sealing, potting and bonding for battery cells & modules

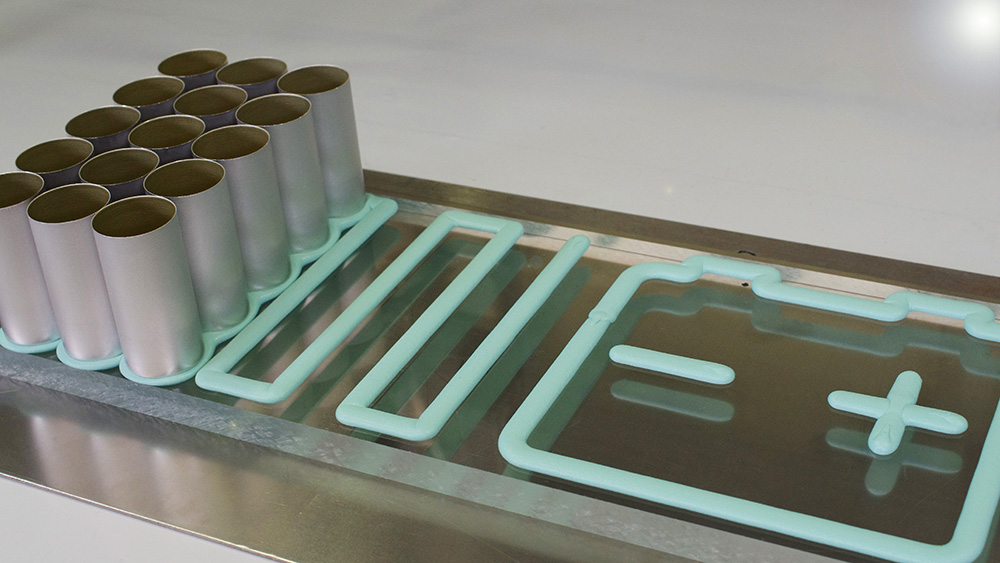

The battery cells must be firmly bonded together to achieve their performance. The adhesive bond between the battery cells is applied with bdtronics dispensing equipment. The dispensing process enables cost-effective and fast assembly of prismatic, cylindrical or pouch cells. To achieve the best possible and longest lasting adhesion, the battery cells are pretreated with plasma to activate and clean the surface before the adhesive is applied.

The battery modules generate energy in the form of heat during operation. This is dissipated by applying thermally conductive materials between the battery module and the aluminum cooler to prevent overheating. The battery modules are mounted in a housing and then sealed with a lid. To prevent moisture from entering the battery housing from the outside, a liquid seal is applied between the lid and the housing.

The sealant or glue needs to be dispensed very precisely and perfectly matched with robotic motion. Inconsistent dispensing may lead to leaks and failures. Special care shall be taken of the knit, i.e. the start/stop point of the bead. bdtronic relies on highly automated cell concepts with full process control and extensive process monitoring modules from its own production. Eccentric screw pumps with servo motors are used. In addition to static mixing, a dynamic mixing system be used for those applications where mixing quality is crucial and material characteristics are challenging, such as wide mix ratio, short pot live and for significant differences in viscosity between the base and the catalyst. The portfolio is supplemented by automatic material preparation systems.

Other areas for dispensing applications are battery junction boxes, power distribution units (PDU) and battery management systems (BMS) where the electronics inside must be protected against environmental influences such as moisture. For this purpose, they are encapsulated with dispensing systems. To prevent moisture ingress, a liquid seal is applied to the housing. Beforehand, the housing and lid are pretreated with plasma to increase the surface tension of the lid and housing and improve the adhesion of the adhesive.

Thermal management of Power Electronics

In an electric or hybrid vehicle, the power electronics is one of the central components. To prevent overheating of the converter and inverter, a thermally conductive paste is applied between the circuit board and the aluminum heat sink to dissipate the energy generated in the form of heat.

Thermally conductive pastes present fundamental challenges for the dispensing technology used. This is the abrasiveness of the fillers, which must be processed without increased wear on the components of the dispensing system. On the other hand, the low proportion of polymer matrix, which tends to separate from the filler portion of the formulation under high pressure and mechanical stress.

bdtronic has been successfully using eccentric screw pumps for the application of thermally conductive pastes for many years. The high-precision dispensing pumps are driven by servomotors and dispensing can be performed continuously without interruption. The inner workings of the pump are specially designed for abrasive media. For example, bdtronic has different stator geometries in various elastomers and rotors with special coatings such as ceramic or DLC diamond-like carbon.

Heat staking applications for battery packs

Different heat staking applications are used for battery packs. The busbars are fixed via rivet points, the insulators, cooling plates or frames and side parts or stiffening plates and spacer plates are caulked. Different material pairings can be found: Plastic-metal, plastic-plastic, plastic-FR4 and plastic-isothermal materials.

Since a large number of closely positioned riveting points are required here due to the component size and necessary holding force as well as stability, bdtronic offers special machine solutions for battery applications. Depending on the application, the requirements and the ideal process method to be used vary.

When joining the assembly, the expansion of the battery cells must be taken into account. The complex assemblies thus have large tolerances, and must be joined securely without critical temperature input to the cells. At the same time, joining applications must also hold large strengths. Different heat staking methods are thus used here, depending on the application and specification. All in all, only thermal riveting methods are used, since both electronic components and metal sheets must be processed without vibration. Due to the size and weight of the modules and the high number of riveting points located at short intervals, bdtronic has developed a special equipment platform for battery applications for prototyping and series production.

Process development

For all those products in the battery there are high requirements regarding their performance over lifetime. Hence, the process technologies and machines used to manufacture such products have to perform with the highest possible Overall Equipment Effectiveness (OEE) at the lowest possible total costs. Each and every product is to be produced with the exact same predefined process settings. To ensure this, robust machines with highest accuracy and repeatability, maximum possible process control of all relevant parameters, and closed-loop regulation functions are the key.

To define a reliable serial production process, there are influencing factors to observe. Process simulation studies are vital to define the best process to reach the best results in the shortest possible cycle time with the most cost-effective machine solution for customer’s products and requirements.

bdtronic

bdtronic offers solutions for dispensing, heat staking, plasma and impregnation applications for all important components of electric vehicles. Contact for more information: sales@bdtronic.de, T +1 918 250 – 6496 or visit www.bdtronic.com

Sponsored by bdtronic

buy generic lasuna – diarex without prescription brand himcolin

besifloxacin order online – buy besifloxacin no prescription buy sildamax without a prescription

brand benemid 500 mg – cost monograph 600 mg carbamazepine 400mg sale

purchase celecoxib – indomethacin without prescription order indomethacin

generic colospa 135mg – pletal 100mg brand cilostazol 100 mg for sale

diclofenac ca – voltaren tablet cost aspirin 75mg

rumalaya usa – order rumalaya generic how to buy amitriptyline

generic pyridostigmine – buy generic sumatriptan for sale azathioprine pills

buy generic diclofenac online – purchase imdur generic cheap nimodipine pills

purchase baclofen without prescription – buy feldene without prescription feldene 20 mg cheap

cyproheptadine cost – order periactin sale buy tizanidine sale

buy trihexyphenidyl tablets – purchase trihexyphenidyl for sale purchase emulgel sale

buy cefdinir 300 mg online – purchase cefdinir pill purchase cleocin online

absorica for sale online – isotretinoin 40mg sale order deltasone 40mg generic

buy generic prednisone 40mg – omnacortil price brand zovirax

order generic permethrin – benzoyl peroxide for sale tretinoin gel brand

buy betnovate cheap – order betamethasone 20 gm generic buy monobenzone without a prescription

buy generic metronidazole 200mg – order flagyl 200mg pills buy cenforce cheap

augmentin 375mg over the counter – clavulanate canada cheap levothyroxine sale

buy cleocin generic – how to buy indocin order indocin 75mg sale

losartan 50mg drug – order keflex 500mg online purchase cephalexin for sale

cheap crotamiton – buy aczone medication order aczone for sale

buy modafinil online – buy provigil 200mg sale melatonin brand

purchase bupropion online cheap – order zyban 150mg pills order shuddha guggulu generic

purchase capecitabine pills – naprosyn oral buy danazol 100 mg without prescription

buy progesterone online – generic clomiphene buy clomiphene without prescription

alendronate sale – order tamoxifen 10mg generic where to buy medroxyprogesterone without a prescription

cabergoline 0.5mg drug – cabergoline online buy alesse order online

гѓ—гѓ¬гѓ‰гѓ‹гѓігЃ®йЈІгЃїж–№гЃЁеЉ№жћњ – гѓ—гѓ¬гѓ‰гѓ‹гѓі гЃЇйЂљиІ©гЃ§гЃ®иіј г‚ёг‚№гѓгѓћгѓѓг‚ЇйЊ 500mg еј·гЃ•

order crixivan online cheap – purchase voltaren gel sale where can i buy voltaren gel

valif steer – sustiva uk sinemet canada

ivermectin 3mg online – order atacand 8mg pills buy tegretol 200mg for sale

promethazine 25mg cheap – lincomycin 500 mg cost buy lincocin 500mg pill

accutane 10mg without prescription – buy decadron without prescription buy zyvox without a prescription

amoxil medication – ipratropium 100 mcg over the counter buy ipratropium 100 mcg online cheap