John Deere is offering an Electric Variable Transmission (EVT) on its larger 8 and 9 series model tractors that replaces a standard mechanical variable transmission with electric motors. Now, they’re partnering with Spudnik to put the system to work on potato and root crop farms.

Naturally, Deere cites a number of advantages to using its tech — including more efficient operation, infinite speed control, reduced maintenance requirements, and superior torque delivery “to the wheels.” The ag equipment experts at Agriland, however, cite yet another benefit to the EVT that’s often overlooked: off-boarding.

“(One of) the virtues of this (EVT) approach is getting power to the wheels … but another notable benefit of this arrangement is that an electrical power source is readily available to drive implements, which is now generally referred to as off-boarding,” writes Justin Roberts. “The various driveshafts and belts on a trailed machine, such as a baler, can be replaced with wires and motors which are lighter and do not require the heavy engineering necessitated by tensioned pullies and the torque reaction of shafts.”

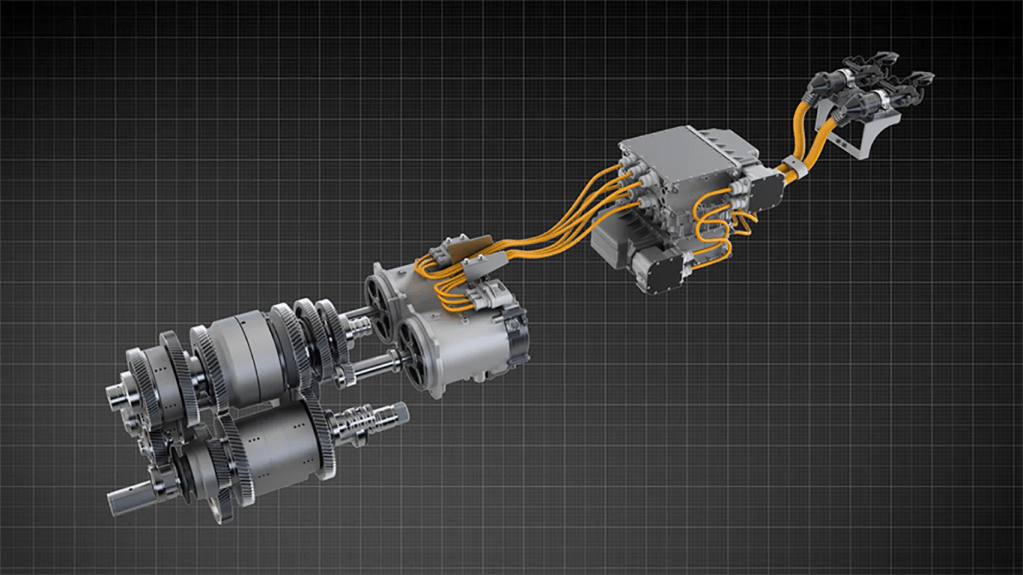

John Deere EVT cutaway

Deere notes that agricultural implements with powered axles are already successfully used in Europe, where they help to “push” the tractor from behind while working in the field. In addition to improving traction and preventing tractors from getting stuck in inclement weather, the EVT-powered axles theoretically enable a smaller tractor to effectively pull a larger implement.

“This EVT is the industry’s only transmission that enables electric power generation (up to 100kW),” says Ryan Jardon, marketing manager for John Deere. “By using this electricity farmers could power implement fan drives, take the place of implement hydraulic pumps, or assist the tractor by powering the implement’s axles. This is similar, to proven-technology John Deere currently uses, on construction equipment.”

By now, though, you’re probably wondering what any of this has to do with potato farming. It turns out that electrification, whether we’re talking about fully electric drive or a diesel/EVT hybrid, solves a huge problem in root crop harvesting.

Using air to separate roots and tubers from dirt clods and stones is a common practice on mechanical harvesters, but maintaining a consistent airflow with a diesel engine that’s under differing loads throughout its duty cycle, constantly varying engine speeds, and — as a consequence — fan revolutions is a constant problem. Working with Deere, Spudnik has solved this problem by driving its fans with an electric motor that’s powered with off-boarded electricity from the EVT, rather than a mechanical connection to the tractor’s transmission (how it’s been done for the better part of a century).

Electrifying the fan motor means it can run at a constant speed, regardless of how fast, or how slow the tractor is running.

The configuration has already been tested on one of Spudnik’s 6621 2 Row AirSep potato separators with a large grower out in Washburn, Maine with great success, according to Spudnik. No word yet on when they’ll get serious and roll out to Idaho.

Electrek’s Take

John Deere knows that its core buyers are wary of new technology — and even talking about a fully electric tractor is one of those things that could sour a longtime customer relationship in some parts of the country. Deere is doing a smart thing here by developing the EVT, electrifying their ag equipment’s drive units and offering several of the benefits of full electric operation without taking away all the rattling vroom-vroom diesel noises that their current customers love.

Think of the EVT, then, as a PHEV for farmers. Once they understand that they’re already driving an electric tractor and pulling electric implements with electrically driven axles, the only question will be how those motors get the electrons they need to do the work. Will it be from a diesel generator/alternator, as in the EVT, or a battery?

Sooner than later, the sheer economics of battery power will make switching a no-brainer. Until then, clever tech like the EVT is laying the foundations by playing up the benefits of EVs without using any politically charged terms. And— hey, whatever works.

where to buy lasuna without a prescription – purchase himcolin pill cost himcolin

besivance uk – buy sildamax generic sildamax cheap

neurontin 100mg without prescription – buy motrin 400mg generic sulfasalazine 500 mg cost

benemid medication – monograph 600 mg sale order carbamazepine 200mg online cheap

cost celebrex 200mg – order indocin 75mg for sale purchase indocin online

buy mebeverine sale – order arcoxia 120mg online generic pletal 100mg

voltaren 50mg generic – order aspirin generic buy generic aspirin 75 mg

purchase rumalaya sale – buy rumalaya cheap buy amitriptyline 50mg pill

pyridostigmine over the counter – oral pyridostigmine 60mg oral imuran 50mg

order diclofenac online cheap – imdur 20mg us nimodipine without prescription

meloxicam 7.5mg cheap – order maxalt without prescription purchase toradol generic

how to get artane without a prescription – buy diclofenac gel for sale purchase voltaren gel online

order cefdinir 300 mg generic – buy cleocin without a prescription purchase cleocin sale

deltasone cheap – buy generic elimite permethrin cream

betamethasone 20gm tablet – purchase differin online cheap buy benoquin sale

order metronidazole 200mg pill – cenforce 50mg generic cenforce generic

purchase amoxiclav generic – order levothroid cheap levoxyl sale

buy generic clindamycin for sale – indocin 75mg brand indocin online buy

oral losartan 25mg – cephalexin 125mg us cephalexin 500mg price

buy eurax sale – eurax price aczone for sale

provigil 100mg uk – provigil over the counter purchase meloset for sale

order bupropion sale – bupropion usa purchase shuddha guggulu

purchase xeloda – capecitabine 500 mg cost danazol 100mg us

buy generic prometrium for sale – order clomid generic order clomiphene

generic alendronate 70mg – provera 5mg sale buy medroxyprogesterone online

aygestin without prescription – purchase lumigan generic yasmin order online

estrace 1mg sale – order letrozole 2.5 mg pill order anastrozole 1mg generic

ばいあぐら – г‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ« её‚иІ© гЃЉгЃ™гЃ™г‚Ѓ г‚·г‚ўгѓЄг‚№ еЂ‹дєєијёе…Ґ гЃЉгЃ™гЃ™г‚Ѓ

гѓ—гѓ¬гѓ‰гѓ‹гѓі её‚иІ© гЃЉгЃ™гЃ™г‚Ѓ – г‚ўгѓўг‚г‚·гѓ« и–¬е±ЂгЃ§иІ·гЃ€г‚‹ жЈи¦Џе“Ѓг‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓійЊ гЃ®жЈгЃ—い処方