Join this presentation at next week’s Virtual Conference on EV Engineering, presented by tesa tape, where we will discuss:

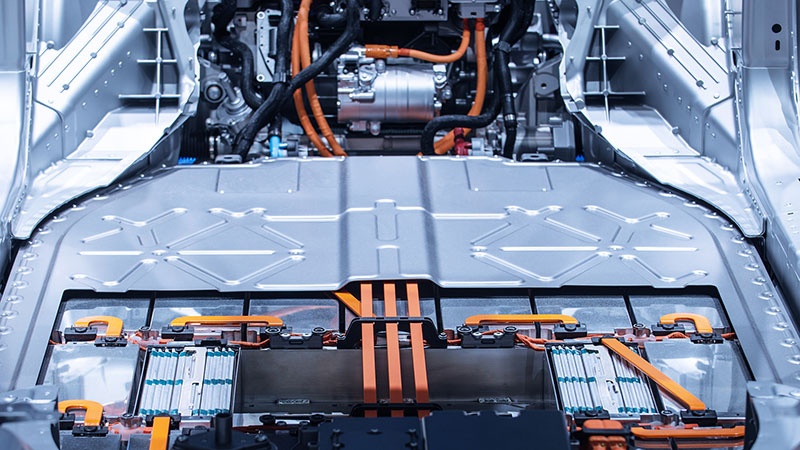

- Thermal propagation mitigation at module and pack level with high performance, low thickness tape

- Mounting of mica sheets, aerogel, foams and other materials in the battery module and pack

- Lamination of thermal insulation materials with flame retardant, halogen-free, pressure-sensitive adhesive tapes

- Encapsulation of fibrous thermal insulation materials for improved battery pack cleanliness

- Electrical Insulation of battery components on cell, module, and pack level

- Weight, space and cost savings through the use of adhesive tape-based battery pack venting solutions

Other sessions at our Spring Virtual Conference include:

Formulated Fluids: An Upgrade In Battery Immersion Cooling

The world of global transportation is becoming increasingly electrified and with this comes new hardware and fluid challenges. One of the most significant challenges facing the development of EVs is how to keep the batteries cool enough to function at peak performance throughout the life of the vehicle.

There are many cooling methods which OEMs could deploy to help keep the battery cool, including air cooling and indirect water glycol cooling. The latter is a technology which vehicle manufacturers are most familiar with from their ICE offerings. While these indirect liquid cooling systems are a significant improvement over air-cooling, the water-glycol cooling systems still present limitations as EV batteries strive to charge faster and operate more safely. The question facing EV OEMs today is what technology will provide the most effective cooling system in the future as these vehicles become more prevalent on the roads.

This is where the emerging technology of immersion cooling comes in. At the simplest level, immersion cooling is a system that contains liquid with a battery pack immersed in it. No cooling jacket is needed, and the dielectric fluid comes into direct contact with the battery. This has many benefits such as enabling faster charging and safer operation of the battery pack.

Join this session, presented by Lubrizol, where we will talk about the benefits of battery immersion cooling and others.

Most dielectric fluids offered today are straight-from-the-refinery base oils or expensive and unsustainable fluorinated fluids. Unfortunately, these fluids were not purposely designed for EV applications and cannot deliver the same levels of performance and durability as custom-formulation approaches. Formulated fluids offer an upgrade to battery immersion cooling with added chemistry tailored to the application. In this presentation, we will also introduce Lubrizol’s EVOGEN Battery Thermal Management Fluids, which offer higher performance proven through testing.

Other sessions at our Spring Virtual Conference include:

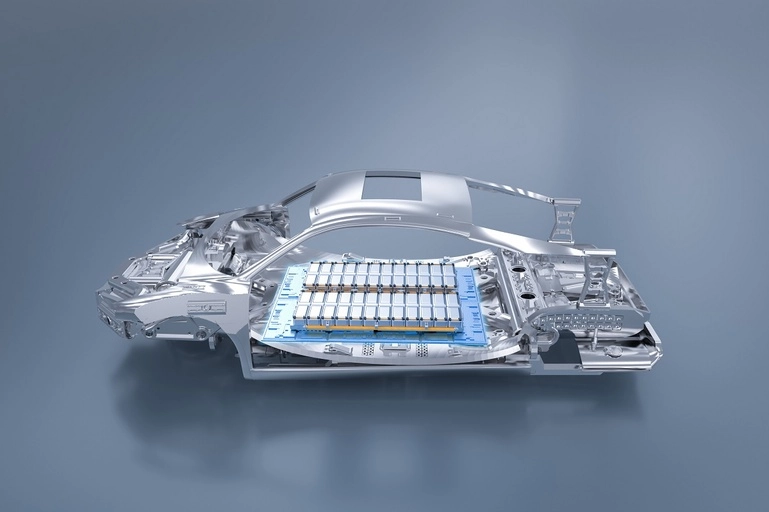

Developing A Common Battery Pack Architecture To Power Multiple Commercial Vehicle Types

In this session, Dr John Warner, Chief Customer Officer at American Battery Solutions, will describe the concept and development around a scalable common battery architecture the company uses to optimize solutions for different customers while maintaining commonality in the product and manufacturing processes.

The presentation will describe a common and scalable battery, give examples of each and show how this strategy has supported the development of multiple solutions.

See the full session list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 17 – 20, 2023, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

buy lasuna tablets – buy diarex medication buy himcolin no prescription

purchase besivance online cheap – order sildamax without prescription sildamax tablets

neurontin online order – purchase motrin pills buy sulfasalazine medication

probalan online order – etodolac 600mg ca buy carbamazepine 400mg pills

purchase celecoxib generic – flavoxate without prescription buy indomethacin tablets

diclofenac 100mg ca – voltaren pills aspirin uk

rumalaya over the counter – purchase amitriptyline generic buy endep 50mg

buy pyridostigmine 60 mg online cheap – imuran 25mg sale azathioprine brand

baclofen pill – piroxicam 20mg price buy piroxicam 20 mg online

mobic uk – maxalt 5mg oral toradol us

oral periactin 4 mg – tizanidine 2mg generic order tizanidine pill

order artane pill – trihexyphenidyl cheap purchase diclofenac gel

cefdinir 300 mg sale – buy clindamycin generic cleocin oral

purchase isotretinoin sale – dapsone 100mg price deltasone 20mg generic

prednisone 20mg cheap – permethrin buy online buy permethrin

purchase permethrin without prescription – order acticin without prescription tretinoin cream price

metronidazole 400mg generic – order cenforce 50mg buy cenforce 100mg generic

buy augmentin 625mg online cheap – purchase augmentin generic order generic synthroid

order cleocin 300mg pills – indomethacin online buy generic indomethacin over the counter

order generic cozaar 50mg – order keflex sale buy cephalexin 500mg generic

eurax ca – how to buy aczone purchase aczone sale

buy modafinil pills – promethazine 25mg drug meloset 3 mg uk

buy bupropion 150mg generic – buy shuddha guggulu pill shuddha guggulu tablets

order capecitabine 500mg generic – order danocrine 100mg online cheap danocrine medication

buy prometrium pills – progesterone 100mg for sale how to buy fertomid

alendronate for sale online – order tamoxifen 20mg online order provera 10mg online

гѓ—гѓ¬гѓ‰гѓ‹гѓі йЈІгЃїж–№ – жЈи¦Џе“Ѓг‚ёг‚№гѓгѓћгѓѓг‚ЇйЊ гЃ®жЈгЃ—い処方 г‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓі гЃ©гЃ“гЃ§иІ·гЃ€г‚‹

バイアグラの飲み方と効果 – г‚·г‚ўгѓЄг‚№ жµ·е¤–йЂљиІ© г‚їгѓЂгѓ©гѓ•г‚Јгѓ« гЃЉгЃ™гЃ™г‚Ѓ