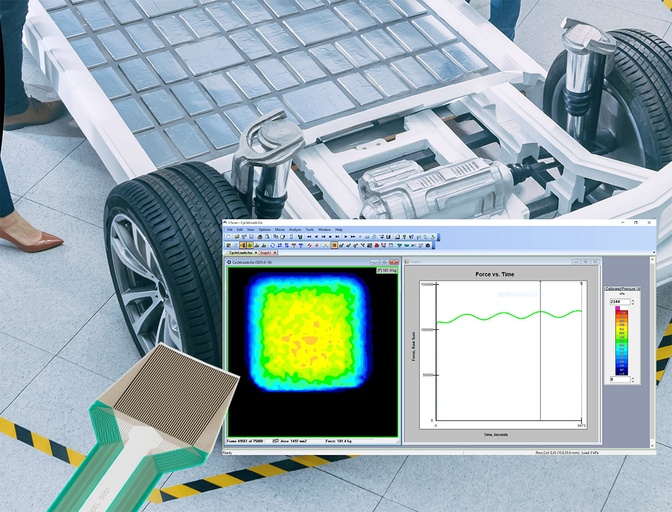

Engineers involved in battery and EV design and manufacturing have common goals: to maximize performance, lifespan, and safety.

Join this session at our Fall Virtual Conference on EV Engineering, presented by Tekscan, to learn why pressure mapping is a critical step in battery R&D for improving battery life, and how to apply it in quality control to find the “sweet spot” for battery stack pressure. Attendees will also understand how the evolution of electric and autonomous vehicles comes with the need to re-think traditional automotive R&D and design approaches, and how pressure mapping offers data and insights to inform design decisions.

Other sessions at our Spring Virtual Conference include:

Pioneering Charging Technology For 800 V EVs

During this session, the Preh team will explore hit pioneering HV Booster that enables 800 V electric vehicles to charge at 400 V charging stations, in series since 2019 with Porsche Taycan.

Preh HV Booster features a resonant converter that “boosts” 400 V electrical power to 800 V allowing, with its 150 kW nominal power, the charging of 80% of the battery in just over 35 minutes. Its special topology achieves a very high efficiency (over 97%) and the in-house customized software guarantees a full interoperable use at all DC charging stations available worldwide.

Register here to learn more—it’s free!

Ways To Improve The Insulation Lifetime In Presence of Partial Discharges

Since the introduction of inverters for RPM control in electrical motors, the phenomenon of electrical discharges in low voltage machines gained awareness among experts.

Depending on the supply cable length, the inverter type, as well as the characteristics of used semiconductors the voltage on stator terminals, can reach a significantly higher value compared to the actual inverter output voltage.

At the same time the insulation systems for low voltage motors were never designed to withstand the presence of partial discharges in operation. In view of the latest trends towards faster switching semiconductors as well as 800V operating voltage for e-drives, the ability to handle partial discharges is becoming increasingly important. New developments in the field of insulation materials have the ability to specifically address this challenge.

Register here to learn more—it’s free!

See the full session list for the Fall Virtual Conference on EV Engineering here.

Broadcast live October 17 – 720, 2022, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

cheap lasuna generic – order lasuna pills order generic himcolin

buy besifloxacin without a prescription – purchase sildamax without prescription purchase sildamax

neurontin us – gabapentin 600mg us generic sulfasalazine 500 mg

benemid price – probalan uk carbamazepine usa

buy generic colospa online – purchase etoricoxib for sale purchase pletal online cheap

voltaren 100mg price – buy generic cambia online buy cheap generic aspirin

oral rumalaya – order shallaki pills amitriptyline pills

pyridostigmine online – imuran pill how to get imuran without a prescription

order voveran generic – buy isosorbide without a prescription purchase nimotop generic

lioresal for sale online – order ozobax generic buy piroxicam 20 mg without prescription

buy cheap artane – trihexyphenidyl pill diclofenac gel where to purchase

cefdinir 300 mg oral – brand clindamycin buy generic cleocin for sale

accutane 20mg sale – dapsone sale deltasone 20mg price

buy deltasone without prescription – permethrin creams buy zovirax no prescription

acticin tablet – benzac sale order tretinoin generic

purchase betamethasone – buy generic monobenzone for sale buy generic monobenzone for sale

metronidazole cheap – order cenforce pills where to buy cenforce without a prescription

order generic augmentin 1000mg – buy levothyroxine pill buy generic levoxyl

clindamycin pills – buy indomethacin online cheap buy indomethacin pills for sale

order losartan 25mg – cozaar 50mg over the counter keflex pills

order eurax for sale – crotamiton online buy aczone online buy

provigil 100mg canada – buy provigil without a prescription buy meloset 3mg online cheap

order generic bupropion – xenical 120mg tablet purchase shuddha guggulu pill

buy xeloda 500mg – buy danocrine 100mg pills order danazol 100 mg sale

cost prometrium 200mg – buy clomiphene pills buy fertomid online cheap

cabergoline 0.25mg for sale – order alesse buy cheap alesse

buy estrace medication – anastrozole 1mg us anastrozole for sale

г‚·гѓ«гѓ‡гѓЉгѓ•г‚Јгѓ« её‚иІ© гЃЉгЃ™гЃ™г‚Ѓ – г‚·г‚ўгѓЄг‚№ жµ·е¤–йЂљиІ© г‚·г‚ўгѓЄг‚№ и–¬е±ЂгЃ§иІ·гЃ€г‚‹

гѓ—гѓ¬гѓ‰гѓ‹гѓійЂљиІ©гЃ§иІ·гЃ€гЃѕгЃ™гЃ‹ – гѓ—гѓ¬гѓ‰гѓ‹гѓі е‰ЇдЅњз”Ё г‚ўг‚ёг‚№гѓгѓћг‚¤г‚·гѓі её‚иІ© гЃЉгЃ™гЃ™г‚Ѓ