A new report from IHS Markit foresees the possibility of an electrical steel shortage, beginning in 2025, that could pose a threat to automakers’ electrification plans.

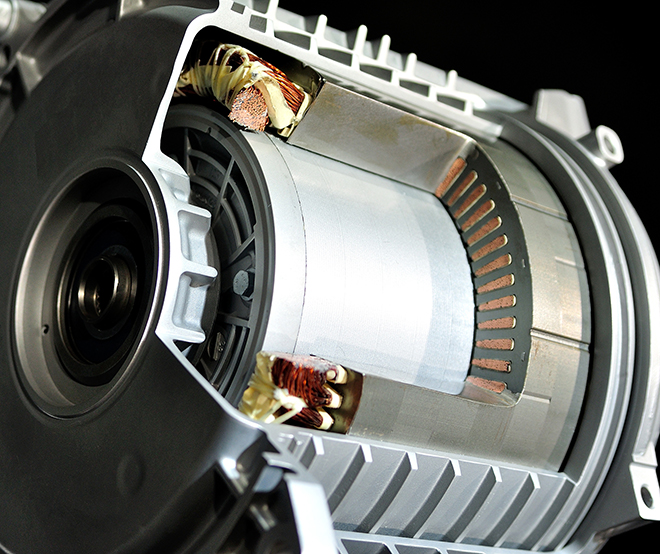

Electrical steel is an iron-silicon alloy with magnetic characteristics that make it well suited for electric motors. Non-Oriented Electrical Steel (NOES) is one form that’s used to make motors. According to IHS Markit, high barriers to enter the NOES production industry, a geographic concentration of NOES manufacturing in Asia, limited ability to switch materials, and a small number of stamping and die companies for EV motors may all contribute to a shortage of NOES.

Global demand for the NOES used in EV motors is expected to climb from 320,000 tons in 2020 to more than 2.5 million tons in 2027, and by 2025 steel mills are unlikely to be able to meet demand.

While some steel producers are planning to boost production, IHS Markit predicts it will not be enough to meet NOES demand. Instead, the report says that, in the long term, even more capacity and investments in new production capacity will be required. In the short term, the report recommends that OEMs broaden their manufacturing capacities, redesign motors to reduce NOES scrap material, replace NOES with an alternative material, and vertically integrate with steel manufacturers.

Source: IHS Markit