The low voltage power architecture used in EV traction inverters drives control electronics and provides gate driver power for the main traction IGBTs/MOSFETs. It must also provide redundancy to meet ASIL requirements. This requirement represents a special challenge as it means the Emergency Power Supply (EPS) must operate from low voltage and high voltage sources requiring it to operate from 30 V to more than 400 V or 800 V (depending on system voltage).

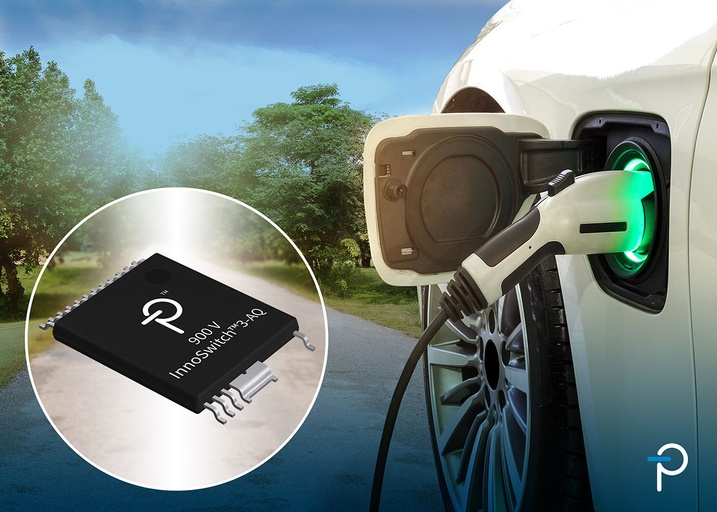

Join this session at the Charged Virtual Conference on EV Engineering, presented by Power Integrations, to learn about a scalable solution, supporting both for 400 V and 800 V systems and significantly reduces part count and PCB area by eliminating additional DC/DC conversion stages. The solution delivers very high efficiency and does not require heatsinks or optocouplers.

Other sessions at our Fall Virtual Conference include:

Electrifying Heavy-Duty with an Intelligent Traction Drive System Solution

Transporting people or goods with heavy-duty vehicles accounts for 34% of US greenhouse gas emissions and about 70% of all US oil use. Electrification is key in the race to net-zero, but heavy-duty in particular faces technology obstacles.

In heavy-duty vehicles, weight is a top consideration. To date, to meet heavy-duty’s long-range needs, a heavier battery is needed, which requires greater energy and power output. Powertrain efficiencies, battery optimization, and creative charging solutions are essential in the transition from diesel to electric, and heavy-duty is ripe for disruptive, clean energy solutions that optimize performance and lower costs.

In this session presented by Exro Technologies, we’ll explore how an intelligent traction drive system integrates with standard direct-drive and axle powertrains and how intelligent coil switching optimizes the powertrain, enhances torque, improves performance, while reducing costs in heavy-duty electric vehicles. Plus, learn how next-generation technology can reduce the number of power electronics required, lowering overall vehicle cost and increasing efficiencies in weight and space in the vehicle.

Register here to learn more—it’s free!

See the full sessions list for the Fall Virtual Conference on EV Engineering here.

Broadcast live October 18 – 21, 2021, the conference content will span the EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

where to buy lasuna without a prescription – buy lasuna medication himcolin oral

buy generic besifloxacin for sale – carbocisteine over the counter sildamax usa

gabapentin 600mg drug – neurontin uk sulfasalazine 500 mg oral

probenecid for sale – carbamazepine without prescription purchase carbamazepine online cheap

buy generic celecoxib online – celecoxib over the counter indomethacin canada

purchase colospa generic – etoricoxib price order pletal 100mg generic

buy voltaren 100mg pills – order voltaren pill order aspirin 75 mg generic

order rumalaya online – elavil 50mg generic buy elavil generic

order mestinon 60 mg sale – imuran 25mg without prescription buy azathioprine without a prescription

lioresal price – order baclofen order feldene 20mg pills

buy mobic pills – buy maxalt 5mg generic buy ketorolac no prescription

periactin 4 mg canada – buy generic zanaflex buy tizanidine medication

artane order online – trihexyphenidyl pills how to purchase diclofenac gel

buy cefdinir 300mg generic – buy clindamycin online cheap buy cleocin gel

isotretinoin 10mg oral – accutane uk purchase deltasone pills

acticin uk – brand acticin retin gel price

betnovate 20 gm sale – benoquin over the counter where to buy benoquin without a prescription

metronidazole 200mg generic – metronidazole online order order cenforce 100mg generic

augmentin 375mg oral – levoxyl cheap levothroid sale

clindamycin generic – order indomethacin online order indomethacin 50mg pills

buy generic hyzaar online – buy losartan generic buy generic keflex

crotamiton over the counter – purchase eurax for sale order aczone without prescription

generic modafinil 100mg – oral provigil 200mg buy melatonin pills

buy zyban online cheap – buy ayurslim online shuddha guggulu online order

buy xeloda 500mg generic – where to buy danazol without a prescription order danocrine 100mg pills

progesterone 200mg usa – cheap ponstel generic fertomid

cheap fosamax 35mg – buy nolvadex 20mg pills buy medroxyprogesterone 10mg online cheap

cost estradiol – anastrozole online order arimidex

dostinex cheap – cheap cabgolin pill oral alesse

гѓ—гѓ¬гѓ‰гѓ‹гѓігЃЇи–¬е±ЂгЃ§иІ·гЃ€г‚‹пјџ – г‚ўгѓўг‚г‚·гѓ«гЃЇи–¬е±ЂгЃ§иІ·гЃ€г‚‹пјџ г‚ёг‚№гѓгѓћгѓѓг‚ЇйЂљиІ©гЃ§иІ·гЃ€гЃѕгЃ™гЃ‹

バイアグラ еЂ¤ж®µ – г‚·г‚ўгѓЄг‚№гЃ®йЈІгЃїж–№гЃЁеЉ№жћњ г‚·г‚ўгѓЄг‚№ – 50mg/100mg