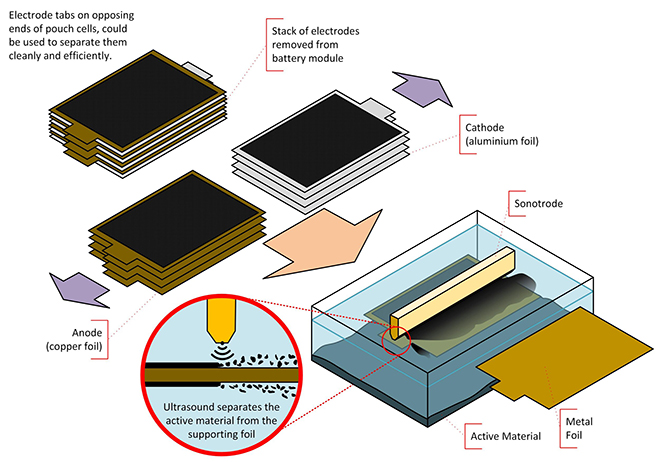

Faraday Institution researchers working on the recycling of lithium-ion batteries at the Universities of Leicester and Birmingham have developed a new method to recover materials from end-of-life EV batteries. The new process uses ultrasonic waves to separate valuable material from the electrodes. The researchers say it delivers a higher purity of recovered materials compared to current separation methods.

The team developed an ultrasonic delamination technique that blasts the active materials from the electrodes, leaving virgin aluminum or copper. This process proved highly effective in removing graphite and lithium nickel manganese cobalt oxides (NMC). Materials recovered using the technique were found to have higher purity than those recovered using conventional recycling approaches, and are potentially easier to use in new electrode manufacture. The approach adapts technology in widespread use in the food preparation industry.

Current delamination recycling techniques use concentrated acids in a batch immersion process. The new ultrasonic technique is a continuous-feed process that uses water or dilute acids as the solvent, so the technique is greener and less expensive to operate. It can delaminate 100 times more electrode material in a given time and volume than existing batch delamination techniques. The research team has tested the technology on the four most common battery types and find that it performs with the same efficiency in each case.

Current recycling methods for lithium-ion battery recycling typically feed end-of-life batteries into a shredder or high-temperature reactor, and use a complex set of physical and chemical processes to produce usable materials streams of the lithium, cobalt, nickel and copper they contain. Such pyrometallurgical and hydrometallurgical recycling routes are energy-intensive and inefficient.

The disassembly of lithium-ion batteries has been shown to recover a high yield (around 80% of the original material) in a purer state than was possible using shredded material.

“This technique works in the same way as a dentist’s ultrasonic descaler, breaking the adhesive bonds between the coating layer and the substrate,” comments Professor Andrew Abbott of the University of Leicester. “It is likely that the initial use of the technology will use production scrap from battery manufacturing facilities as the feedstock and feed recycled material straight back into the battery production line, possibly at the same site.”

Source: The Faraday Institution

Your expertise on this subject shines through in this post.