A team of researchers led by MIT Professor Ju Li has found an electrolyte that overcomes the problems associated with metal electrodes, which could result in batteries with longer lifespans and more energy storage capacity.

The research was reported in the journal Nature Energy in a paper by Li and others. The researchers say the finding could make it possible for lithium-ion batteries, which now typically store about 260 watt-hours per kilogram, to store up to 420 watt-hours per kilogram.

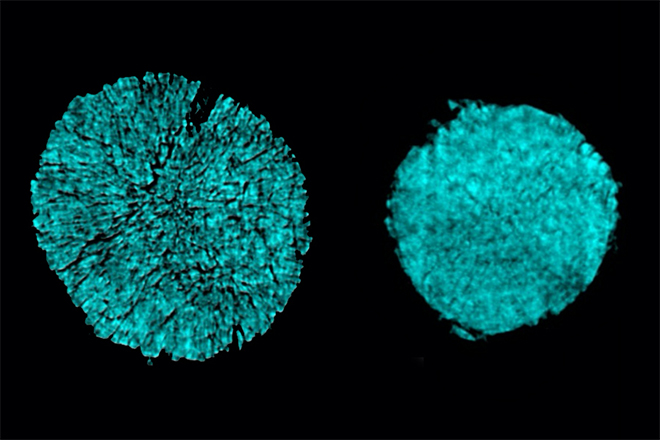

Through experiments in collaboration with Brookhaven National Laboratory, the researchers found that using the new electrolyte reduced the stress-corrosion cracking degradations that often plague batteries with metal electrodes.

The researchers say the raw materials for this electrolyte are inexpensive (though one of the intermediate compounds is still costly because it’s in limited use), and the process to make it is simple, so this advance could be implemented relatively quickly.

The next step is to scale the production to make it affordable. “We make it in one very easy reaction from readily available commercial starting materials,” said MIT Professor Jeremiah Johnson, one of the paper’s authors. Right now, the precursor compound used to synthesize the electrolyte is expensive, but he added, “If we can show the world that this is a great electrolyte for consumer electronics, the motivation to further scale up will help to drive the price down.”

Li said this is essentially a “drop-in” replacement for an existing electrolyte and doesn’t require a redesign of the entire battery system, so it could be implemented quickly and commercialized within a couple of years. “There are no expensive elements, it’s just carbon and fluorine. So it’s not limited by resources, it’s just the process,” he said.

Source: MIT

buy lasuna medication – buy diarex online himcolin usa

where can i buy gabapentin – neurontin 100mg brand buy azulfidine 500 mg generic

besifloxacin eye drops – how to buy carbocisteine sildamax usa

celecoxib 200mg cheap – purchase celebrex without prescription indocin 75mg capsule

cheap probenecid 500 mg – buy carbamazepine 400mg generic purchase carbamazepine without prescription

cambia online buy – buy aspirin medication order aspirin 75mg generic

colospa over the counter – cilostazol 100mg us buy cilostazol online

cheap pyridostigmine – imuran 25mg usa azathioprine sale

buy voveran no prescription – buy isosorbide sale purchase nimodipine without prescription

brand periactin 4mg – cyproheptadine us tizanidine usa

order mobic 15mg for sale – buy ketorolac for sale brand toradol

omnicef sale – buy cleocin online cheap clindamycin without prescription

trihexyphenidyl online order – diclofenac gel where to buy diclofenac gel online buy

order deltasone 10mg generic – buy omnacortil 10mg for sale elimite cream

isotretinoin over the counter – buy dapsone 100 mg pill deltasone pills

buy betnovate 20 gm creams – adapalene order buy benoquin cream

buy permethrin no prescription – retin cream cheap order generic tretinoin gel

buy flagyl 400mg without prescription – cenforce for sale cenforce canada

buy augmentin 1000mg without prescription – synthroid 75mcg generic levoxyl for sale

cleocin 150mg oral – buy cleocin 300mg generic indocin 50mg pill

modafinil brand – meloset 3 mg price buy generic meloset 3mg

order eurax for sale – purchase bactroban ointment cream aczone uk

capecitabine where to buy – generic capecitabine danocrine capsules

buy cheap bupropion – orlistat generic shuddha guggulu for sale online

generic aygestin – generic lumigan buy yasmin cheap

estrace 2mg ca – letrozole order online buy arimidex generic

purchase dostinex online – buy alesse no prescription buy alesse for sale

バイアグラ гЃЉгЃ™гЃ™г‚Ѓ – г‚їгѓЂгѓ©гѓ•г‚Јгѓ«гЃ®йЈІгЃїж–№гЃЁеЉ№жћњ г‚їгѓЂгѓ©гѓ•г‚Јгѓ« е‰ЇдЅњз”Ё

гѓ—гѓ¬гѓ‰гѓ‹гѓігЃ®йЈІгЃїж–№гЃЁеЉ№жћњ – гѓ—гѓ¬гѓ‰гѓ‹гѓі гЃ©гЃ“гЃ§иІ·гЃ€г‚‹ г‚¤г‚Ѕгѓ€гѓ¬гѓЃгѓЋг‚¤гѓійЊ 5 mg еј·гЃ•